Researchers have developed a new system that makes delta robots faster and more precise, paving the way for better performance in industries like food processing, electronics, and pharmaceuticals.

These robots are known for their speed and accuracy, but this breakthrough could take them to the next level.

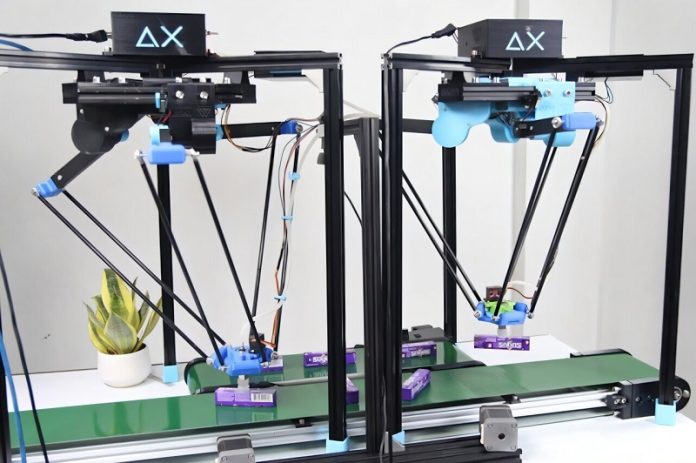

Delta robots are unique machines with a fixed base and three arms that move a platform to complete tasks. Unlike traditional robots, their special design lets them work quickly and precisely.

They are widely used for high-speed “pick-and-place” jobs, such as assembling tiny electronics, sorting food items, or packaging products.

A team from the Technical University in Babylon, Iraq—Riyadh A. Sarhan, Zaid H. Rashid, and Mohammed S. Hassan—has created a new control system to improve these robots even further.

Their approach combines two advanced technologies: fuzzy logic and an adaptive neuro-fuzzy inference system (ANFIS).

Fuzzy logic helps robots make decisions in uncertain conditions, while ANFIS uses artificial intelligence to adapt and learn. Together, these tools help the robots manage their complex movements with greater accuracy and reliability.

This smarter control system allows delta robots to perform their tasks more efficiently, even in changing environments. For example, if a factory condition shifts, the robot can adapt on the fly without losing accuracy. This means manufacturers can expect better quality, faster production, and less downtime on their assembly lines.

The researchers believe this technology will help industries improve automation and reduce costs. By making delta robots smarter and more responsive, factories can produce goods more quickly and with fewer errors.

As automation becomes a bigger part of our lives, innovations like this ensure that robots stay ahead of the curve, making industrial processes smoother, faster, and more reliable.

This is just the beginning of what smarter delta robots can achieve!

Source: Inderscience.