Researchers have made an exciting breakthrough to improve desalination technology by eliminating “dead zones” in fluid flow.

These dead zones slow down the movement of water and make the process less efficient.

By creating a new electrode design with tapered flow channels, engineers at the University of Illinois Urbana-Champaign have found a way to make desalination more efficient and less energy-intensive.

Desalination is the process of removing salt from seawater to make it drinkable.

The most common method, reverse osmosis, involves pushing water through a membrane that filters out salt. However, this method uses a lot of energy and is expensive.

An alternative approach, the battery-based desalination method, uses electricity to pull salt out of the water. While promising, it has its own challenges, such as the need to push water through tiny, uneven spaces in the electrodes, which also requires energy.

Kyle Smith, a professor of mechanical science and engineering at Illinois, led the research team to address these challenges.

“Traditional electrodes still need energy to pump water through because they don’t have structured flow paths,” Smith explained. “By creating channels within the electrodes, we can improve how water flows, reducing energy use and potentially outperforming reverse osmosis in the future.”

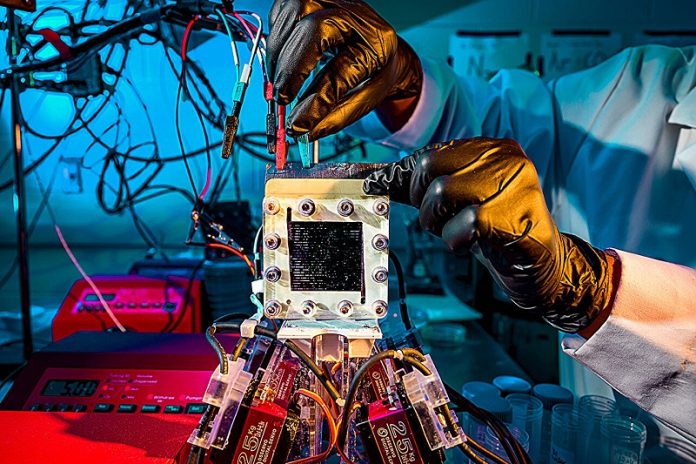

The team’s innovation builds on years of research into how water flows through electrodes. They designed electrodes with small, straight channels, known as interdigitated flow fields (IDFFs), to improve water movement.

While these straight channels were a step forward, they still created dead zones—areas where water movement slowed due to uneven pressure.

To solve this, the researchers created electrodes with tapered channels instead of straight ones. The tapered design improved water flow by two to three times compared to straight channels, making the process significantly more efficient.

These findings were published in the journal Electrochimica Acta.

“We initially discovered that straight channels caused pressure drops and uneven water distribution,” said Habib Rahman, a graduate student and co-author of the study. “So, we experimented with 28 different designs to understand how to improve flow and eventually developed this tapered-channel technique.”

While the design shows great promise, there are challenges to scaling it up for industrial use. One of the biggest hurdles is the time required to create these tiny channels in the electrodes. However, the researchers are optimistic that this challenge can be solved.

What makes this breakthrough even more exciting is its potential beyond desalination. According to Smith, the tapered-channel design can be applied to other technologies that rely on fluid flow, such as fuel cells, batteries, carbon capture devices, and systems for recovering lithium or other valuable materials.

“Unlike previous channel-tapering approaches, which were based on trial and error, our method is rooted in physics-based principles,” Smith said. “This ensures uniform flow while minimizing pressure drops.”

This innovation could lead to more efficient desalination systems and better technologies for clean energy and environmental sustainability. The future of water purification and energy storage just got a little brighter, thanks to this creative solution.