Scientists at the Department of Energy’s Oak Ridge National Laboratory (ORNL) have developed a groundbreaking method to upcycle plastic waste into new, high-quality materials with better properties than the originals.

This innovative approach could help address the global plastic waste crisis, where over 450 million tons of plastic are discarded each year, but only 9% is recycled.

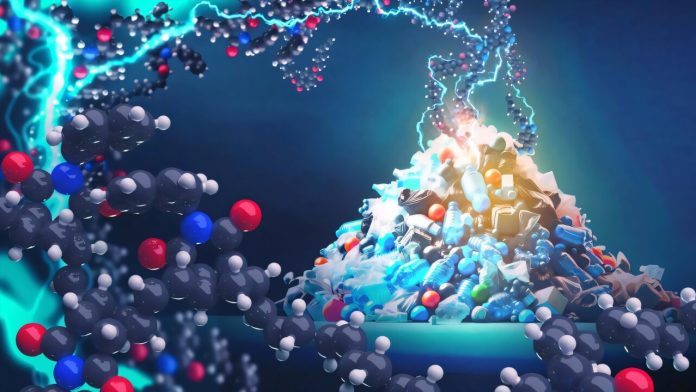

The new method involves “editing” the molecular building blocks of plastics, known as polymers.

Polymers are long chains of molecules whose structure determines a plastic’s properties, like strength, flexibility, and heat resistance. By rearranging these chains, researchers can create new plastics with enhanced characteristics.

“This is like CRISPR for plastics,” said Jeffrey Foster, the lead researcher. CRISPR is a tool used to edit genes, but instead of altering DNA, ORNL scientists are editing polymer chains.

This precise method is a major improvement over traditional recycling, which involves melting down plastics and hoping for the best, often resulting in lower-quality materials.

The team focused on two common yet rarely recycled plastics: soft polybutadiene, often used in rubber tires, and tough acrylonitrile butadiene styrene (ABS), found in toys, computer keyboards, and kitchen appliances.

These materials usually end up in landfills because they are difficult to recycle effectively.

The researchers began by dissolving the plastics in a solvent called dichloromethane and using a ruthenium catalyst to drive chemical reactions. This process was conducted at just 40°C (104°F) over two hours, making it energy-efficient compared to traditional recycling methods.

The process works by breaking and reforming double bonds between carbon atoms in the polymer chains.

This allows the polymer’s building blocks to be rearranged and combined with other materials, creating plastics with new properties. The upcycled materials could be softer, stretchier, or easier to mold into durable products.

The team used two advanced chemical methods to upcycle plastics:

- Ring-opening metathesis polymerization: This process opens carbon rings in the polymer structure and elongates them into chains.

- Cross metathesis: This process swaps parts of polymer chains, combining subunits from one polymer with another.

Together, these methods allowed the scientists to efficiently modify the plastics’ structure and create valuable new materials.

Unlike traditional recycling, which degrades plastic quality with each cycle, this method preserves and enhances the materials. It also has a “high atom economy,” meaning most of the material used in the process is recovered, minimizing waste. Additionally, the process requires less energy and produces fewer emissions than conventional methods.

“The new process addresses a significant part of the plastic waste stream,” Foster said. “It’s an exciting way to conserve materials that would otherwise end up in landfills.”

The ORNL team believes their method could be expanded to other types of plastics, helping reduce the environmental impact of hard-to-recycle materials. They’re particularly interested in applying this technique to thermoset plastics, like epoxy resins and polyurethane, which cannot be remelted or reshaped due to their cross-linked molecular structure.

The researchers are also working to make the process even more eco-friendly by optimizing the solvents used. They hope to scale up the technology to handle large volumes of waste and further explore how changing polymer subunits can create high-performance materials.

By transforming waste into valuable resources, this method offers a step toward a circular economy, where plastics are repurposed instead of discarded. If widely adopted, it could significantly reduce plastic pollution and revolutionize recycling.