A team of scientists from Nanyang Technological University, Singapore (NTU Singapore), has developed an innovative 3D concrete printing method that captures carbon dioxide (CO₂).

This breakthrough offers a greener and more efficient way to build structures, helping to reduce the environmental impact of the construction industry.

The construction sector is one of the biggest contributors to global CO₂ emissions, responsible for about 8% of the world’s total emissions. Cement, a key material in construction, alone produces 1.6 billion metric tons of CO₂ annually.

The new method, published in the journal Carbon Capture Science & Technology, offers a solution by incorporating captured CO₂ directly into the concrete mix during the 3D printing process.

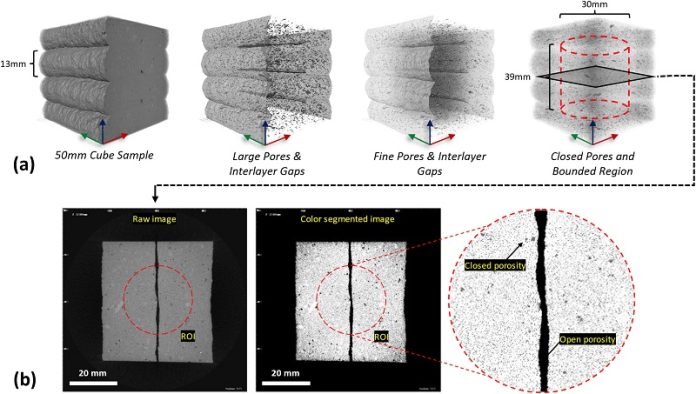

Here’s how it works: The 3D concrete printer is connected to pumps that inject steam and CO₂ into the concrete as it’s being printed.

The CO₂ reacts with the components in the concrete, turning into a solid form that remains trapped (sequestered) inside the material. At the same time, steam helps the concrete absorb more CO₂ and improves its properties.

This innovative method doesn’t just reduce emissions—it makes the concrete stronger and easier to use. In lab tests, the research team found that the printed concrete had:

- 36.8% greater strength in compression (how much weight it can bear).

- 45.3% greater strength in bending (how much it can flex before breaking).

- 50% better printability, meaning the concrete can be shaped and printed more efficiently.

On top of these improvements, the method also captures 38% more CO₂ compared to traditional 3D printing methods.

This not only reduces emissions but also turns waste CO₂, such as that produced by power plants, into a useful resource.

Professor Tan Ming Jen, the principal investigator from NTU’s School of Mechanical and Aerospace Engineering, explained, “The construction industry emits a lot of carbon, but our new method gives us a way to reduce that impact. By capturing CO₂ and using it to print stronger concrete structures, we are showing how the sector can become more sustainable.”

The team believes this technology could play an important role in global efforts to combat climate change.

It could lead to eco-friendly buildings, reduce material waste, and decrease reliance on energy-intensive construction processes like reinforced concrete.

Ph.D. researcher Lim Sean Gip, the first author of the study, emphasized, “We are at a critical time for climate action. Our technology can help make the construction industry greener and more efficient.”

This groundbreaking work demonstrates how science and technology can work together to tackle global challenges. By transforming harmful CO₂ into stronger, sustainable materials, scientists are paving the way for a cleaner and smarter construction future.

Source: KSR.