A team of engineers at the Hong Kong University of Science and Technology (HKUST) has made a groundbreaking invention in semiconductor technology.

They have developed the first-ever deep-ultraviolet (UVC) microLED display chips designed for lithography machines.

These chips promise to revolutionize the process of making semiconductors by reducing costs and improving efficiency in creating advanced electronic circuits.

Lithography machines are vital for producing semiconductor chips. They use ultraviolet light to create tiny patterns on a thin layer called a photoresist, forming the basic structure of integrated circuits.

Traditionally, lithography machines rely on mercury lamps or conventional deep-UV LED light sources.

However, these methods come with several challenges, including large device sizes, low light efficiency, high energy use, and insufficient power for precise work.

To address these issues, the research team, led by Professor Kwok Hoi-Sing, designed a new kind of deep-UV microLED display array.

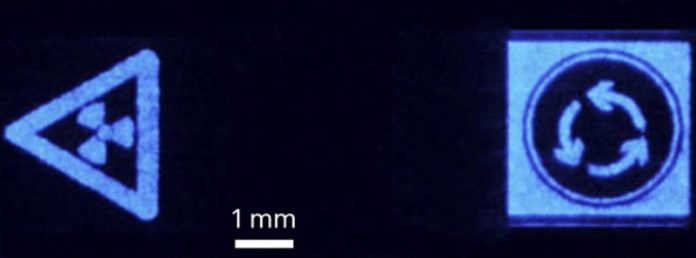

Their invention enables “maskless photolithography,” a cutting-edge process that doesn’t require expensive lithography masks.

Instead, the patterns for the circuits can be directly projected using the microLEDs. This breakthrough allows the photoresist layer to be exposed to UV light more quickly, significantly reducing manufacturing time and cost.

The team built a prototype lithography machine using their deep-UV microLED display chips. These chips improve critical aspects of the manufacturing process, such as:

- Light Efficiency: The microLEDs provide high power and efficiency, reducing energy consumption.

- Precision: The chips can produce high-resolution patterns, allowing for intricate circuit designs.

- Heat Management: The new design handles heat better, making the process more stable.

- Flexibility: Maskless lithography allows manufacturers to quickly adjust designs without needing new masks, making the process more customizable and cost-effective.

Professor Kwok shared that the team achieved significant milestones, including creating smaller devices with lower power requirements, higher light efficiency, and better resolution. These advancements position their technology as a leader in the global semiconductor industry.

Dr. Feng Feng, a postdoctoral researcher in the project, highlighted that their deep-UV microLED chips outperform other similar technologies in every key measure, such as device size, optical power density, and overall performance. Their work represents a major step forward in semiconductor manufacturing.

The team’s research, published in Nature Photonics under the title “High-Power AlGaN Deep-Ultraviolet Micro-Light-Emitting Diode Displays for Maskless Photolithography,” has already earned widespread recognition.

It was named one of the top 10 breakthroughs in China’s third-generation semiconductor technology at the 10th International Forum on Wide Bandgap Semiconductors in 2024.

Looking ahead, the researchers plan to improve their technology further.

They aim to enhance the performance of AlGaN deep-UV microLEDs and create even higher-resolution display screens, ranging from 2k to 8k resolution. These advancements could lead to even more precise and efficient semiconductor manufacturing processes.

This invention marks a significant step forward in the semiconductor industry, potentially making advanced electronics cheaper and easier to produce while paving the way for future innovations.