Researchers at the University of Michigan have discovered a new use for rice hulls, the tough outer shells of rice grains.

When burned, rice hulls produce a form of carbon that could nearly double the energy storage capacity of lithium-ion and sodium-ion batteries.

This breakthrough could make batteries more efficient, sustainable, and affordable.

The new material, called “hard carbon,” is a special type of carbon that forms during the burning process.

Until now, scientists believed hard carbon could only be made by heating organic materials like agricultural waste in an oxygen-free environment at extremely high temperatures.

However, this study shows that hard carbon can also be created through combustion—a simpler and more cost-effective method.

Rice hulls are often treated as waste, with most ending up in landfills. However, they can also be burned to generate green energy.

For example, Wadham Energy in California burns rice hulls to produce electricity, generating enough power each year for about 22,000 homes.

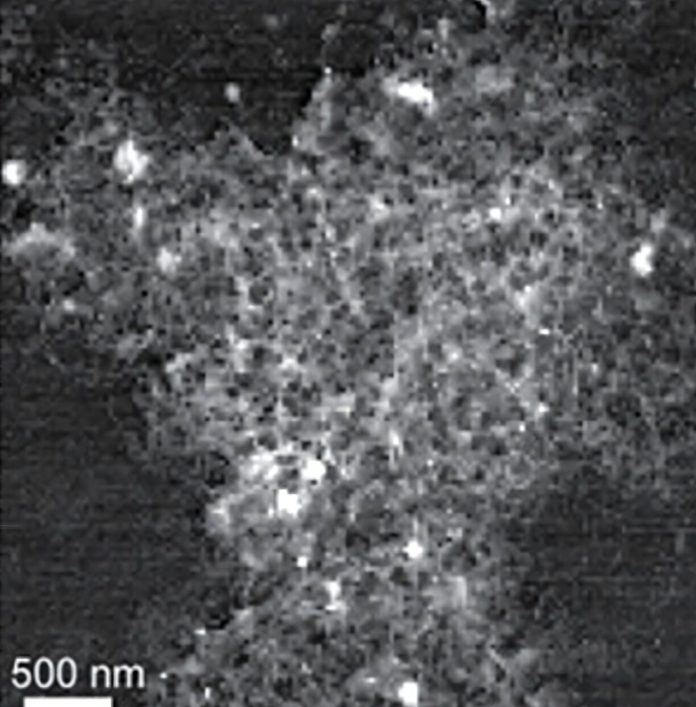

The carbon left over from burning rice hulls, once treated, contains a mix of amorphous carbon and tiny graphite-like structures. This unique structure makes it ideal for use in battery electrodes, where energy is stored and released.

When tested in lithium-ion batteries, hard carbon made from rice hulls outperformed both commercial hard carbon and traditional graphite.

A gram of rice hull hard carbon can store over 700 milliampere-hours (mAh) of charge—nearly twice as much as graphite (370 mAh) and significantly more than commercial hard carbon (500 mAh).

This means batteries using this material could last longer or store more energy without increasing their size.

The nanoporous structure of rice hull hard carbon is thought to contribute to its impressive energy capacity.

Using rice hulls to create hard carbon is not only effective but also environmentally friendly. Unlike producing graphite, which releases large amounts of carbon dioxide (CO2), burning rice hulls is carbon-neutral.

The CO2 released during burning comes from what the rice plant absorbed during photosynthesis.

Additionally, this process could reduce the need to import graphite from countries like China and Mexico, offering a sustainable, domestic alternative.

With around 20 billion pounds of rice grown annually in the United States, there’s plenty of potential to scale up this technology. The research team, with support from U-M Innovation Partnerships, has applied for a patent and is looking for partners to bring this breakthrough to market.

This discovery could play a major role in meeting the growing demand for batteries, especially for electric vehicles and renewable energy storage, while reducing both costs and environmental impact.