Steel bridges are critical for transportation, especially long-span designs that rely on orthotropic steel bridge decks (OSDs).

These decks are lightweight and efficient at carrying heavy loads, but their complex structure makes them prone to cracks from stress, known as fatigue cracking, which can pose serious safety risks.

Traditional inspection methods, like visual checks or magnetic testing, often miss small or hidden cracks.

Even advanced methods like Phased Array Ultrasonic Testing (PAUT) have limitations. This has created a strong demand for better crack detection technologies.

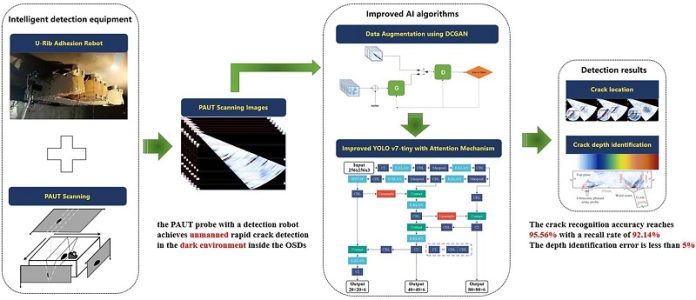

Now, researchers from Southwest Jiaotong University and The Hong Kong Polytechnic University have developed a robotic system that combines ultrasonic technology with artificial intelligence (AI) to improve bridge inspections.

Their work, published in the Journal of Infrastructure Intelligence and Resilience, could revolutionize how we monitor bridge safety.

The system uses a robotic platform equipped with ultrasonic sensors to scan bridge decks automatically, reducing the need for human inspectors.

It’s powered by deep learning models, including a tool called YOLOv7-tiny, which can quickly and accurately identify cracks in real-time.

The researchers also used a deep learning technique called DCGAN to enhance the training data, helping the AI learn to detect cracks more effectively.

One of the system’s standout features is its ability to not only find cracks but also measure their depth with high precision.

By analyzing the strength of sound echoes from the cracks, it can estimate their depth with a margin of error below 5%, matching the accuracy of more complex methods like Time of Flight Diffraction (TOFD).

This system has many advantages:

- It speeds up the inspection process.

- It reduces human error.

- It can spot cracks that are small or overlapping, which traditional methods might miss.

- It helps identify problems early, potentially preventing bridge failures.

Dr. Hong-ye Gou, one of the lead researchers, emphasized how this technology could make bridges safer and last longer by catching issues before they become serious.

With applications in transportation and infrastructure maintenance, this robotic inspection system could lower maintenance costs, extend the lifespan of bridges, and improve safety for the public.

By automating inspections, it sets a new standard for monitoring critical infrastructure, ensuring reliability for generations to come.

Source: TranSpread.