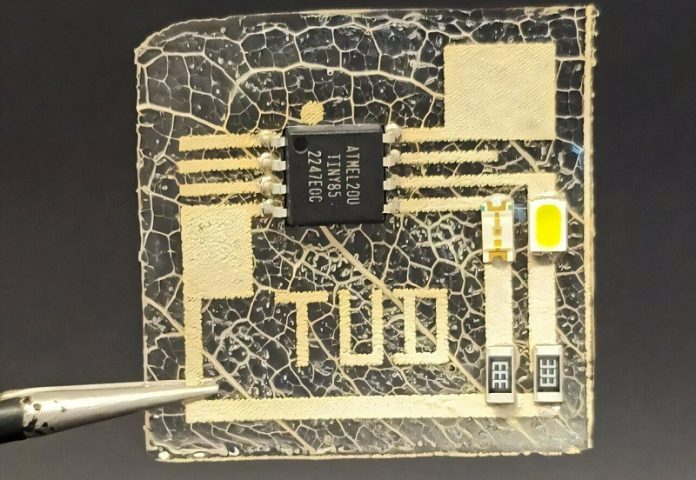

A research team at TUD Dresden University of Technology, led by Professor Karl Leo, has developed a groundbreaking technology called “Leaftronics.”

Inspired by the natural design of leaves, this innovation could transform the electronics industry by introducing biodegradable materials for electronic devices.

These findings, published in Science Advances, offer a sustainable solution to tackle the growing problem of electronic waste.

Why do we need leaftronics?

Every year, the world generates more than 60 million tons of electronic waste, and most of it—over 75%—is never collected or recycled. Electronic devices, from toys to smartphones, rely on circuit boards made from materials that are neither recyclable nor biodegradable, adding to this waste.

Efforts to create biodegradable materials have faced challenges. While natural polymers have been explored, they often lack the heat and chemical resistance needed for electronics. The balance between biodegradability and stability has been a major obstacle—until now.

Nature’s secret weapon: leaf-like structures

The Leaftronics breakthrough uses the structure of real leaves to solve this problem. Leaves have a natural framework called quasi-fractal lignocellulose, which provides strength and flexibility to hold living cells. The research team adapted this natural design to reinforce biodegradable polymer films.

“We discovered that these natural structures can make polymers stronger, even at high temperatures, without losing their ability to break down in the environment,” explained Dr. Hans Kleemann, a member of the research team.

Dr. Rakesh R. Nair, who worked on this project for his Ph.D., added that the lignocellulose skeleton stabilizes the films thermally and mechanically. These reinforced films are smooth enough for advanced electronics like organic light-emitting diodes (OLEDs), making them practical for real-world applications.

The reinforced films are strong enough to endure the manufacturing process for modern electronic circuits, including soldering.

Once the device reaches the end of its life, the substrate can be broken down in soil or processed in biogas plants. This allows electronic components and precious materials to be recycled while reducing overall waste.

A green future for electronics

Leaftronics represents a major step toward a sustainable electronics industry.

These biodegradable materials have a carbon footprint three times lower than paper and could be used in a wide range of industries, from consumer electronics to renewable energy.

“This is an exciting blend of nature and technology,” said Professor Karl Leo. “It offers a sustainable solution to reduce waste and fight climate change, paving the way for a circular economy in electronics.”

With innovations like Leaftronics, the dream of high-tech gadgets that don’t harm the environment is becoming a reality.