Manufacturing industries like cement, steel, chemicals, and paper require a tremendous amount of heat, which is usually produced by burning fossil fuels.

This reliance on fossil fuels makes these industries some of the hardest to decarbonize.

But a breakthrough from Electrified Thermal Solutions, a company co-founded by MIT researcher Daniel Stack, could change that.

Stack and his team have developed thermal batteries that use electricity to generate extreme heat, up to 3,272°F, enough to power even the most demanding industrial processes.

The system stores heat in specially designed conductive firebricks, paving the way for industries to shift from fossil fuels to renewable energy.

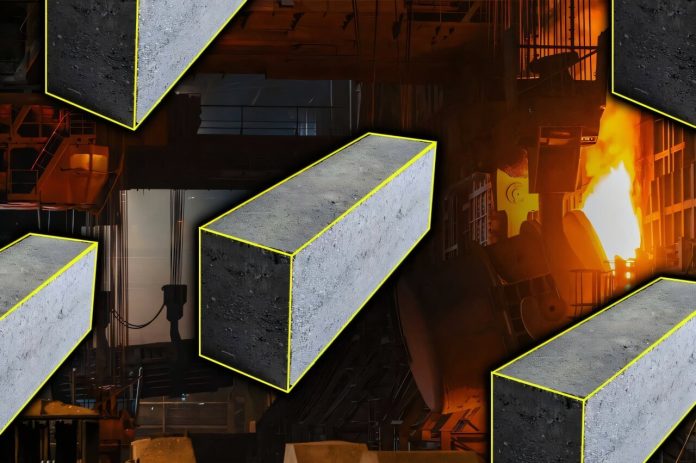

Thermal batteries are based on firebricks, a type of clay brick used for centuries in fireplaces and ovens to store and withstand heat.

Stack and his mentor, MIT scientist Charles Forsberg, modified traditional firebricks to make them electrically conductive. These bricks heat up directly when electricity passes through them, eliminating the need for fragile electric heaters that break down at high temperatures.

The modified firebricks, known as e-Bricks, can store heat for hours and release it by heating air or gas to extremely high temperatures. These bricks are produced using existing manufacturing processes, making them inexpensive and easy to scale.

The thermal battery system stores and releases energy using arrays of e-Bricks contained in insulated metal boxes.

A single system can hold about 25 megawatt-hours of energy and produce heat equivalent to 5 megawatts, making it capable of meeting the heating needs of large industrial operations.

One of the major advantages of this technology is its ability to run on renewable electricity, such as wind or solar power. In parts of the U.S., electricity prices drop significantly—or even go negative—during off-peak hours. This allows the thermal batteries to charge when electricity is cheapest, making them a cost-effective alternative to fossil fuels.

“Technologies like our Joule Hive Thermal Battery let industries use clean electricity and compete on cost with fossil fuels, all while reducing emissions,” Stack explains.

Electrified Thermal is working with a wide range of industries, including cement, steel, glass, food, and chemicals. These sectors all face the same challenge: finding a way to generate affordable, high-temperature heat without relying on fossil fuels.

The company is currently building a commercial-scale system, which will be operational in seven months. This system will demonstrate how thermal batteries can meet real-world industrial needs and help manufacturers transition to zero-carbon heat sources.

The e-Bricks are designed to be quickly and easily produced using existing supply chains, which makes scaling up the technology feasible on a global level.

“From the start, we engineered these systems to be scalable and affordable,” Stack says. “If industries want to decarbonize, there’s no cheaper way than using clean electricity to generate heat.”

Electrified Thermal’s thermal batteries represent a significant step in decarbonizing heavy industry, which accounts for a large portion of global carbon emissions. By replacing fossil fuels with clean electricity, this technology has the potential to transform industrial heating and play a key role in the energy transition.

“We aim to be the leading technology driving this change,” Stack says. “Our goal is for a significant portion of the world’s energy to flow through our systems as we move toward a cleaner future.”