Imagine a material so thin it’s just one atom thick, yet incredibly strong, light, and flexible.

This is graphene, a “miracle material” that has captivated scientists for years.

Now, European researchers are working to bring graphene and other ultra-thin materials into our everyday technology.

Dr. Inge Asselberghs, a leading scientist at Imec, a nanoelectronics research institute in Belgium, is at the forefront of this mission. She’s part of a global team trying to turn graphene’s lab success into real-world breakthroughs.

The team has built a special prototype manufacturing facility for graphene and other 2D materials as part of the 2D Experimental Pilot Line (2D-EPL).

This project combines the expertise of 11 universities, research institutes, and companies across six European countries.

Their goal is to create new high-tech products like advanced electronics, sensors, and photonics using graphene.

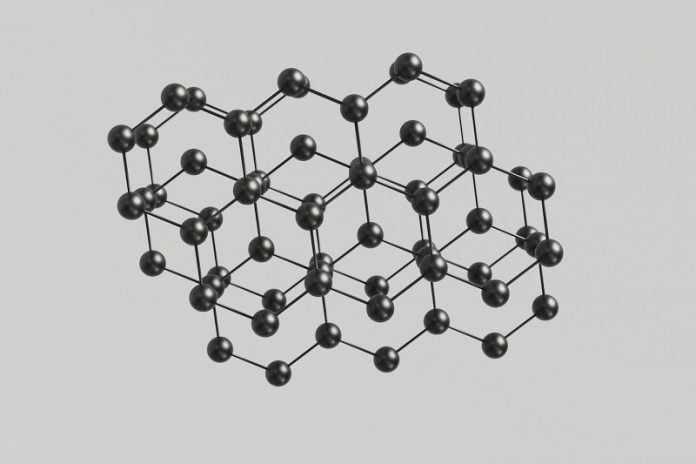

Graphene is made from a single layer of carbon atoms arranged in a honeycomb pattern. Despite its thinness, it’s incredibly strong—about 200 times stronger than steel. It’s also a superb conductor of heat and electricity, making it perfect for everything from faster internet to better batteries.

Graphene’s unique qualities have excited scientists and engineers. “The hype started as soon as graphene was discovered. It was much stronger than initially anticipated,” says Dr. Asselberghs.

Recognizing its potential, the European Union launched the Graphene Flagship initiative in 2013, a 10-year project with a €1 billion budget. The initiative has brought together 178 partners to explore how graphene and other 2D materials can transform industries.

A major challenge for the team is figuring out how to mass-produce graphene and integrate it into electronic devices. They’ve started by adapting existing manufacturing processes to handle graphene in the same way factories handle silicon wafers. These wafers, which are thin, round slices of material, are essential components in electronics.

Producing graphene on these wafers isn’t easy. Its thinness makes it very delicate, and even a tiny speck of dust can ruin it. To solve this, the team developed a process to protect graphene with a thin polymer layer before transferring it onto a silicon base. This requires ultra-clean rooms and precise equipment.

At Imec’s facility, researchers have built an assembly line to process graphene on wafers that are 200 to 300 mm wide. These sizes are standard in the electronics industry, making it easier for companies to adopt graphene when the technology is ready.

While graphene gets most of the attention, other 2D materials are also exciting researchers. Some of these materials, like silicon, can act as semiconductors, opening the door to even more technological advances.

Companies and industries are already showing interest. Researchers have received design requests for specific products, from super-fast transistors to sharper medical sensors. According to Harm Knoops, a Dutch researcher from Oxford Instruments Plasma Technology, “It could mean data centers use less power, your internet is faster, or you have a medical device connected to your phone.”

One advantage of graphene is that it’s made from carbon, one of the most abundant elements on Earth. This makes it relatively cheap to produce on a large scale. Experts believe graphene could eventually be used to create new kinds of devices we can’t even imagine yet.

While graphene isn’t quite ready for widespread industrial use, researchers are optimistic about its future. Once it reaches the market, it could transform how we use electronics, making devices faster, more efficient, and more powerful.

From sharper sensors to faster internet, graphene’s potential is enormous. It may still be in the development phase, but one thing is clear: the future of technology is about to get a lot thinner—and a lot more exciting.