A team of researchers from the University of Southern California (USC) has developed a breakthrough way to recycle carbon fiber composites, commonly used in car panels, airplanes, and even wind turbines.

These lightweight and strong materials, known as carbon fiber reinforced polymers (CFRPs), are popular in industries focused on energy efficiency.

However, they’ve posed a recycling problem, often ending up in landfills when they reach the end of their life.

Professor Travis Williams from USC’s Dornsife College of Letters, Arts, and Sciences, who led the study, explained why recycling CFRPs has been so challenging.

“We didn’t have a practical way to recycle them,” he said.

“As a result, most composites today end up as waste, creating a huge environmental issue.” Carbon fiber composites are found in everyday items, from bicycles to cars and even prosthetics, making this problem widespread.

So, what makes carbon fiber composites so tricky to recycle? CFRPs are made of two main parts: carbon fibers and a plastic-like material called a polymer matrix, which binds everything together.

The fibers are thin, strong, and lightweight, while the matrix holds everything in place.

But unlike plastic, CFRPs don’t melt down easily, and separating the carbon fibers from the matrix without damaging them has proven difficult.

Until now, the most common approach has been to burn away the matrix material, which destroys it and is only applied to about 1% of composite waste.

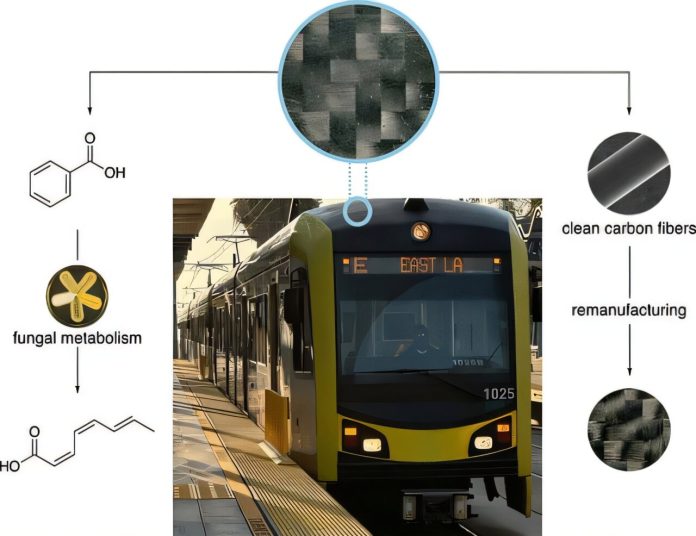

Williams and his team, which included chemical engineers and biotechnology experts, discovered a new method that lets them recycle both parts of the composite—saving the carbon fibers and the polymer matrix without burning anything.

Their approach recovers over 97% of the original strength of the fibers, meaning they’re strong enough to be used again in new products, reducing waste and offering a sustainable alternative to disposal.

To make this work, the team used a special fungus called Aspergillus nidulans, which can break down the polymer matrix after it’s separated from the carbon fibers.

The fungus, developed by Berl Oakley’s lab at the University of Kansas, can turn the matrix into a valuable material called OTA (octa-2,4,6-trienoic acid). OTA has exciting potential uses, such as in anti-inflammatory drugs or antibiotics. Co-researcher Clay C.C. Wang, who specializes in pharmacology, noted that this discovery opens new ways to transform waste into resources for medical applications.

The new method addresses a rising environmental challenge. By 2030, thousands of airplanes made from CFRPs will be retired, and by 2050, discarded wind turbines alone could produce hundreds of thousands of tons of CFRP waste.

Williams believes that this recycling method will play a crucial role in creating more sustainable practices, reducing the environmental impact of these durable yet hard-to-recycle materials.

This new technique turns waste into valuable materials, providing an eco-friendly solution at a time when demand for carbon fiber composites is only growing. The USC team’s breakthrough offers hope for the future of recycling and sustainable manufacturing.