With climate change pushing the demand for renewable energy, solar power has become a key solution.

In countries like Spain, solar photovoltaic energy generation jumped by 28% in 2023, accounting for over 20% of the nation’s total energy.

However, while solar cells have clear environmental benefits, there’s still room for improvement in terms of sustainability.

The goal is to create solar cells that are lightweight, cost-effective, flexible, and eco-friendly, making it possible to power buildings, infrastructure, IoT systems, and even vehicles.

Scientists are now exploring alternatives to current materials that can maintain or even improve efficiency while being more sustainable.

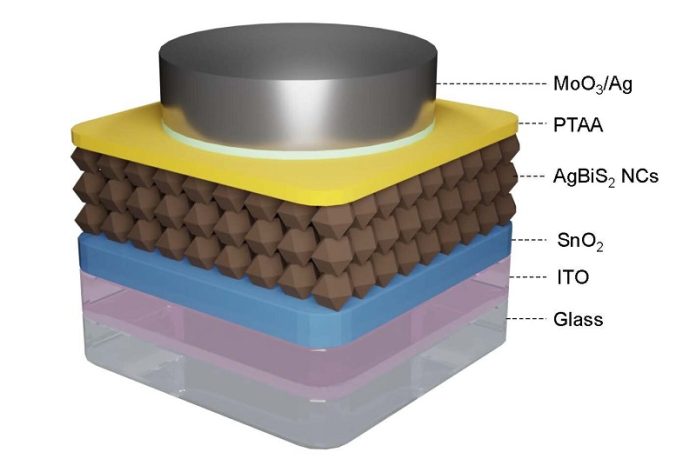

One promising material is colloidal silver bismuth sulfide (AgBiS2) nanocrystals. These nanocrystals are known for their strong ability to absorb light, allowing the creation of ultra-thin solar cell films.

Previously, scientists used a multi-step layering process to build these solar cells. However, this method can be expensive and wasteful, making it less ideal for large-scale production.

Researchers have been working to replace the multi-step process with a simpler, single-step approach using AgBiS2 nanocrystal “inks.” Despite progress, these inks often had defects on their surfaces that lowered the efficiency of the solar cells. These surface defects trapped electrical charges produced by sunlight, reducing the overall performance of the device.

A team of researchers at the Institute of Photonic Sciences (ICFO) in Spain recently achieved a breakthrough in improving these solar cells.

Led by ICREA Professor Gerasimos Konstantatos, the researchers developed a new technique called post-deposition in situ passivation (P-DIP). This method effectively removed the surface defects in the nanocrystal ink films, creating smoother pathways for electrical charges to move.

Dr. Jae Taek Oh, the study’s first author, explains, “Think of it like a bumpy road that slows down cars. Our passivation method repaves the road, allowing cars to travel smoothly.” By removing these “bumps,” or defects, the P-DIP strategy improved the quality of the nanocrystal film, enabling the solar cells to perform better.

The team achieved this by adding a special molecular agent containing chlorine to the AgBiS2 nanocrystal ink. This agent helped stabilize and evenly disperse the nanocrystals, leading to smooth coatings. After forming the film, the researchers applied an additional passivation treatment, which extended the lifetime of electrical charges and balanced their transport within the film. These improvements resulted in solar cells with a power conversion efficiency of around 10%—a new record for AgBiS2 nanocrystal-based solar cells.

The ICFO team’s work represents a significant step toward creating more efficient and eco-friendly solar cells. By focusing on simplifying the manufacturing process and improving the quality of the materials, they have demonstrated a promising solution for sustainable solar energy.

This new technology could lead to more accessible, affordable, and environmentally friendly solar power in the future.

Source: ICFO.