A research team has developed a groundbreaking technology that could help recycle waste heat from industrial and transportation sectors like factories, cars, and ships.

By improving the properties of a material called bismuth telluride (Bi-Te), they’ve made it possible to convert waste heat—specifically below 200℃—into electricity more efficiently.

This technology could have a big impact on thermoelectric power generators, which use temperature differences to generate electrical energy.

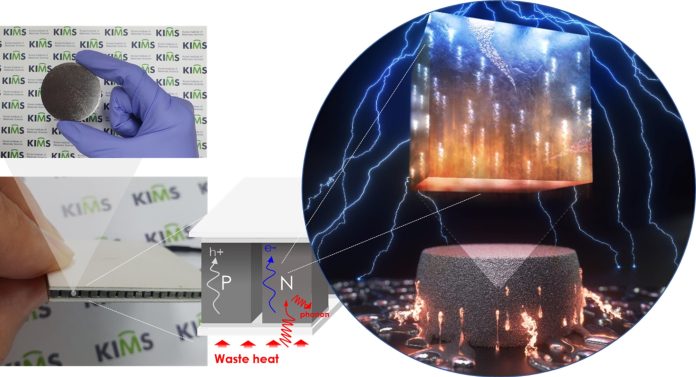

Thermoelectric power generators are made up of two types of semiconductors: p-type and n-type.

While p-type materials have been improving over the years, progress with n-type materials has been slower, mainly because it’s harder to control their composition and structure.

The n-type materials play a crucial role in the performance of thermoelectric generators, and the lack of advancement has limited the technology’s commercial use.

However, this research team has achieved a breakthrough.

By using antimony (Sb) instead of selenium (Se) as the doping material in n-type bismuth telluride, they’ve created a much more efficient n-type material.

Doping materials are substances added to semiconductors to improve their electrical properties. The team’s innovation in using antimony has helped improve the material’s performance significantly.

One of the key advancements in this research was the ability to artificially create “atomic defects” in the material. These defects help generate more electrons, boosting electrical conductivity.

The team also created “dislocation networks” during the manufacturing process, which scatter heat-carrying particles called lattice phonons.

This process lowers the material’s thermal conductivity while enhancing its electrical conductivity, making it more efficient at converting heat into electricity.

The team used a method called powder metallurgy to manufacture the thermoelectric material.

This process involves placing powdered material into a mold, heating it, and then sintering it (a process of bonding the powder particles together), allowing the material to be shaped and sized easily.

The result is an n-type thermoelectric material with more than double the electrical conductivity and significantly reduced thermal conductivity.

This new technology could help recycle heat from a variety of sources, including industrial waste and even human body heat. The thermoelectric power generator market is growing and is expected to reach $1.18 billion globally by 2029.

Dr. Kyung Tae Kim, who led the research, said, “This study has helped solve the long-standing challenge of improving n-type thermoelectric semiconductors, paving the way for better recycling of waste heat below 200℃.”

The team is now working on developing a thermoelectric power plant and collaborating with Hyundai to explore further applications of their technology.