Researchers have discovered a way to make polyvinyl chloride (PVC) plastics more durable and less likely to release harmful microplastics.

PVC is one of the most commonly used plastics in the world, found in products like toys, medical packaging, and construction materials.

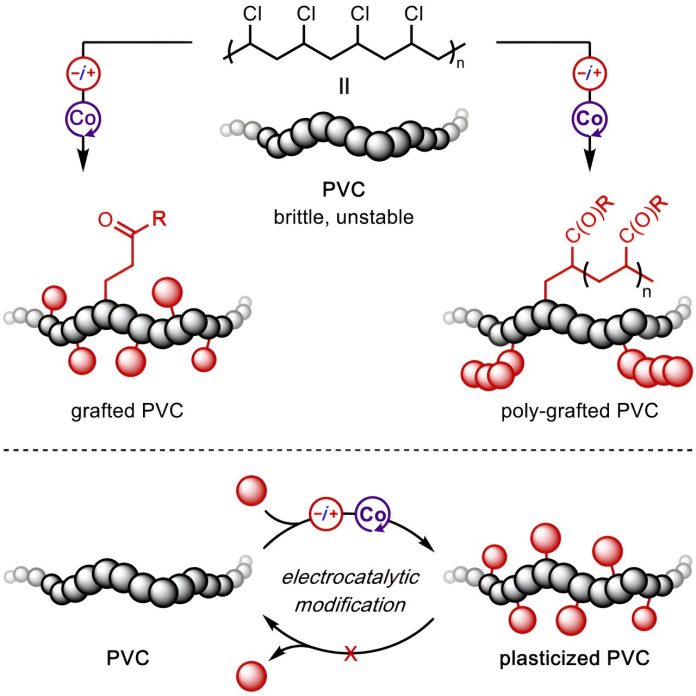

However, pure PVC is brittle and weak, so manufacturers add chemical stabilizers called plasticizers to improve its strength and heat resistance.

Unfortunately, over time, these plasticizers can break down, allowing the plastic to weaken and shed dangerous microplastics into the environment.

A team of researchers, led by Christo Sevov, a chemistry professor at The Ohio State University, has now developed a method to solve this problem.

Their technique uses electricity to permanently attach the chemical additives to the PVC molecules, preventing the breakdown that leads to the release of microplastics.

Their study was published in the journal Chem.

Instead of simply mixing plasticizers into the PVC, the new process chemically bonds them to the polymer itself.

“By grafting the plasticizers onto the PVC backbone, we make it more durable and resistant to chemical changes,” said Sevov.

This approach allows scientists to control the properties of PVC, making it harder, softer, or stretchier as needed for different products.

The research team faced some challenges because traditional methods for modifying small molecules don’t always work on larger ones like PVC.

Through trial and error, they optimized the process and found a way to successfully modify the large PVC molecules.

This breakthrough could have a big impact on the environment.

Microplastics, tiny pieces of plastic that pollute the air, water, and food supply, are harmful to humans and wildlife. It’s estimated that the average person consumes between 78,000 and 211,000 microplastic particles every year.

By making PVC more durable and preventing it from breaking down into microplastics, Sevov’s method could help reduce this pollution.

Recycling PVC is also difficult because the high temperatures needed can further damage the plastic, making it less effective.

With this new technique, however, PVC could potentially be reused many more times before it starts to deteriorate. This would extend the life of PVC products and make them more environmentally friendly.

While this discovery is promising, there is still more work to be done before it can be scaled up for commercial use. “We’ve laid the groundwork for a solution, but there’s still more to explore before we fully solve the microplastic problem,” Sevov said.

This new method has the potential to revolutionize the production and reuse of PVC, making it safer for both consumers and the environment.