Researchers at the University of Virginia (UVA) have developed a new type of 3D-printed concrete that is both stronger and more environmentally friendly.

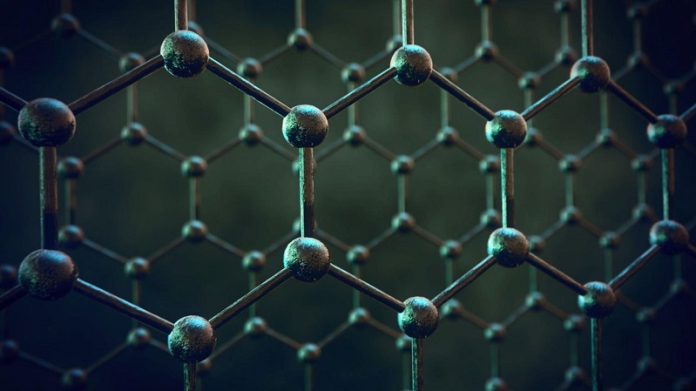

By adding graphene—a material known for its remarkable strength—to a special cement mixture made with limestone and calcined clay (LC2), the team successfully created a concrete that can significantly reduce carbon emissions by up to 31%.

This advancement is a big step forward in making 3D-printed construction more sustainable.

The project was led by Osman Ozbulut, a professor in UVA’s Department of Civil and Environmental Engineering, with key contributions from visiting scholar Tuğba Baytak and doctoral researcher Tawfeeq Gdeh.

They worked with a team at UVA’s Resilient and Advanced Infrastructure Laboratory and collaborated with the Virginia Transportation Research Council (VTRC).

“Our goal was to design a printable concrete that performs better and is more eco-friendly,” explained Ozbulut.

The addition of graphene to the LC2 cement mixture was a key breakthrough, as it significantly improved the material’s durability and flexibility. These properties are crucial for 3D-printed structures, which need to be both strong and capable of withstanding various stresses.

Graphene’s outstanding mechanical properties made it an ideal choice for enhancing the LC2 cement.

When combined with this innovative cement mixture, the graphene significantly boosted the concrete’s performance, allowing it to be used in a variety of construction projects.

One of the most important parts of the study was a Life Cycle Assessment (LCA), which was conducted by postdoctoral researcher Zhangfan Jiang in collaboration with environmental engineering professor Lisa Colosi Peterson. The LCA provided a comprehensive view of the environmental impact of this new concrete.

According to Jiang, “Being able to see the full environmental footprint of this new concrete was important.”

The LCA showed that the graphene-enhanced LC2 concrete could cut greenhouse gas emissions by roughly 31% compared to traditional 3D-printed concrete. This reduction in carbon emissions is a significant achievement, especially as the construction industry continues to seek greener alternatives.

“It’s rewarding to see science push us toward greener building practices,” said Colosi Peterson.

The collaboration with the VTRC allowed the team to explore the real-world potential of their new material. They were able to test and verify its properties for transportation infrastructure, demonstrating its practical applications beyond just laboratory experiments. Gabriel Arce, a research scientist from VTRC, also played a key role in the project.

“This kind of innovation is essential for the future of construction,” said Baytak, a doctoral researcher from Istanbul Technical University and visiting scholar at UVA. “I’m proud to be part of the team driving this forward.”

The researchers are optimistic that their graphene-enhanced 3D-printed concrete will lead to more sustainable construction practices and inspire further innovations in eco-friendly building materials.

The findings of this research were published in the Journal of Building Engineering under the title “Rheological, Mechanical, and Environmental Performance of Printable Graphene-Enhanced Cementitious Composites with Limestone and Calcined Clay,” 2024.