A team of engineers from Monash University has developed a groundbreaking electrified reactor that could help industries like chemical manufacturing, fertilizer production, and hydrogen generation significantly reduce their carbon emissions, improve efficiency, and lower costs.

This new reactor offers a more sustainable alternative to traditional high-temperature processes that rely on fossil fuels.

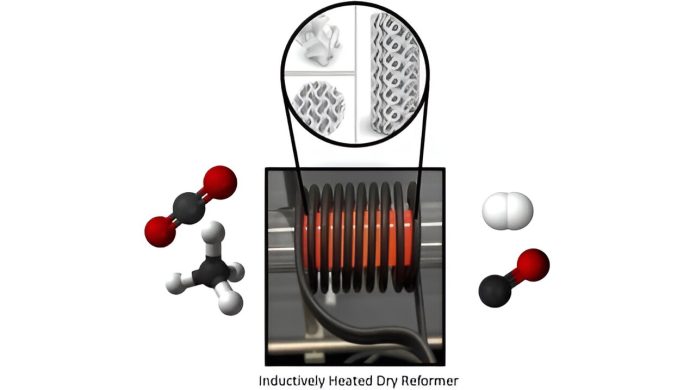

The reactor is designed for the dry reforming of methane (DRM), a process used to produce chemicals such as methanol, ammonia, and synthetic fuels.

Typically, these industries rely on burning fossil fuels to generate the high temperatures needed (over 900°C), which contributes heavily to global carbon emissions.

Published in the journal Applied Catalysis B: Environment and Energy, the study reveals that the electrified reactor can reduce carbon emissions by 60% compared to conventional methods, all while boosting efficiency.

Powered by renewable energy, the reactor eliminates the need for fossil fuel combustion, making it a more eco-friendly option for industrial processes.

Professor Akshat Tanksale, lead researcher and Deputy Director of the ARC Research Hub for Carbon Utilization and Recycling, highlighted that this innovation is essential for industries looking to reduce their carbon footprint without sacrificing productivity or increasing costs.

“Our reactor allows industries to cut both emissions and operational costs by replacing fossil fuels with sustainable energy sources,” Professor Tanksale explained. “It also achieves a 96% conversion rate of methane into usable energy, far better than the 75% seen with traditional methods.”

One of the key advantages of the reactor is its compact and modular design, which makes it easy to integrate into existing industrial systems. This means companies can quickly adopt the technology without significant changes to their infrastructure.

This new technology could be particularly beneficial for ammonia production, plastics, and fuel production industries, which heavily rely on methane reforming. By adopting this electrified reactor, these sectors could drastically reduce their emissions while maintaining high levels of productivity.