Industrial processes in the United States are a major source of carbon dioxide emissions, accounting for about a third of the country’s total—more than the combined emissions from all passenger vehicles, trucks, and airplanes.

Reducing these emissions is crucial for tackling climate change, but it’s a challenging task.

However, researchers at Stanford Engineering have developed a promising solution: a new type of electric reactor that could significantly cut industrial emissions by using electricity instead of fossil fuels to generate the intense heat required for many manufacturing processes.

This innovative reactor, described in a study published in Joule, is not only more efficient than traditional fossil fuel-powered reactors, but it’s also smaller, cheaper, and easier to operate.

“We’ve created an electrified reactor that pushes the limits of performance and uses green electricity to power it,” said Jonathan Fan, an associate professor of electrical engineering at Stanford and the senior author of the study.

How the electric reactor works

Traditional industrial reactors generate heat by burning fossil fuels, which then heats a fluid that flows through pipes—similar to how a boiler sends hot water through radiators in a house.

This method requires a lot of infrastructure and results in significant heat loss along the way.

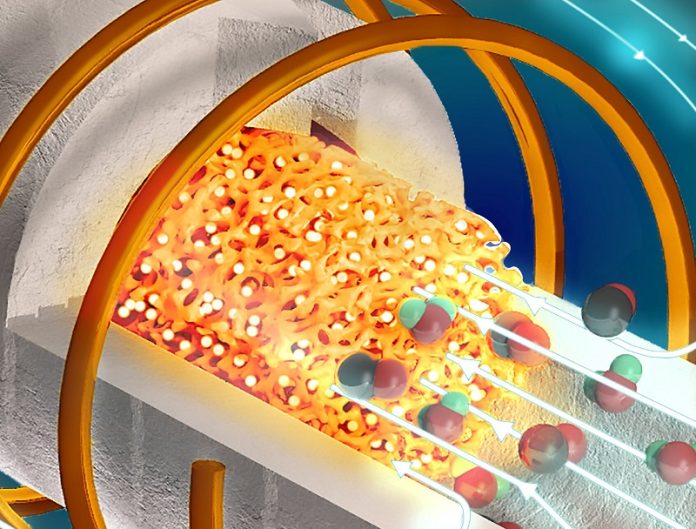

The new reactor uses magnetic induction to generate heat, a process similar to how induction stovetops work.

Instead of transporting heat through pipes, this reactor creates heat directly inside its core by using interactions between electric currents and magnetic fields.

For example, if you wrap a wire around a steel rod and run an alternating current through the wire, it creates a magnetic field that induces a current in the steel.

Since steel is not a perfect conductor, some of that current turns into heat, warming the entire piece of steel at once rather than heating it from the outside in.

However, adapting this induction process for industrial use isn’t as simple as just turning up the heat. Industrial reactors need to distribute heat evenly in all directions and be much more efficient than a typical kitchen appliance.

The Stanford researchers achieved this by using high-frequency currents and materials that are poor conductors of electricity, which maximize efficiency.

They developed a lattice structure made from a ceramic material that doesn’t conduct electricity well, and placed this lattice in the reactor’s core.

The structure is designed to have voids, which further reduce electrical conductivity and allow the addition of catalysts—materials that need to be heated to initiate chemical reactions. This design makes the reactor much smaller and more efficient than traditional models.

Proving the Concept

The researchers tested their reactor with a chemical reaction called the reverse water gas shift reaction, which requires high heat to turn captured carbon dioxide into a valuable gas that can be used to create sustainable fuels.

In their tests, the reactor was over 85% efficient, meaning it converted nearly all the electrical energy into usable heat. The reaction also occurred at the predicted rate, which is often not the case with new reactor designs.

“As we scale up these reactors or operate them at higher temperatures, they only become more efficient,” Fan explained. “This is the advantage of electrification—we’re not just replacing old technology, we’re improving it.”

The team is now working to scale up this technology and apply it to other industrial processes, such as carbon capture and cement manufacturing. They’re also collaborating with industry partners to explore how this technology can be integrated into existing systems and conducting economic analyses to make it more affordable.

“Electrification gives us a chance to reinvent industrial infrastructure,” Fan said. “We’re breaking through existing limitations, shrinking and simplifying reactors, and, importantly, decarbonizing them. This is just the beginning of what’s possible for industrial decarbonization.”