Scientists at Nagoya University in Japan have developed a new method to grow tiny metal nanowires (NWs) that could be important for future electronics.

Nanowires are extremely small wires, much thinner than a human hair, and they are expected to play a big role in making next-generation electronics like circuits, solar cells, and LED lights more efficient.

However, producing nanowires on a large scale while keeping them pure and high-quality has been difficult—until now.

The new method was created by a team led by Professor Yasuhiro Kimura at Nagoya University’s Graduate School of Engineering.

Their breakthrough could make it easier to mass-produce nanowires made from pure metals, a key step forward for electronics manufacturing. This research was recently published in the journal Science.

Nanowires are made by transporting atoms, which are the tiniest particles of matter, to specific places.

Typically, this is done by moving the atoms in a gas form, but this is tricky to achieve with metals. As a result, making enough nanowires for practical use has been a challenge.

The new solution: atomic diffusion

To solve this, the research team used a process called atomic diffusion.

Atomic diffusion is when atoms move from areas where there are a lot of them to areas where there are fewer, usually with the help of heat.

The team used this process on a solid material instead of gas, which is different from other methods.

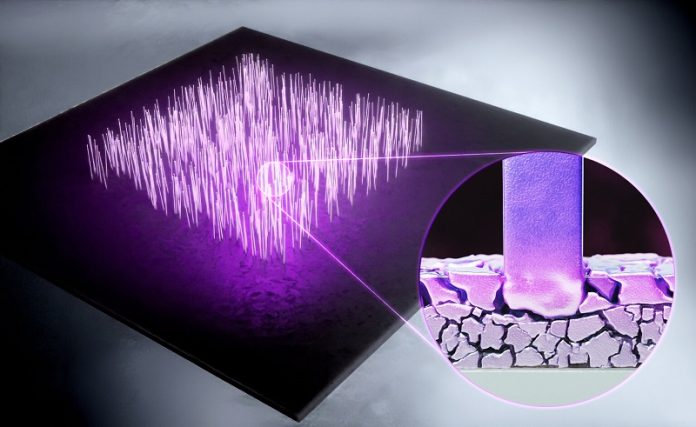

They started with a thin aluminum film made of crystal grains, which are tiny pieces of crystal inside the material.

They then used ion beam irradiation—essentially shooting ion particles at the aluminum film.

This caused changes in the crystal grains, making them larger at the surface and creating stress inside the material. This stress allowed atoms to flow more easily.

Next, they applied heat, which pushed atoms from the smaller grains at the bottom of the film to the larger grains at the top. This upward flow of atoms led to the growth of aluminum nanowires in large quantities.

With this method, the team was able to dramatically increase the number of nanowires they could grow, from about 200,000 nanowires per square centimeter to 18 million per square centimeter.

This is a huge improvement in the ability to produce nanowires in large amounts.

These aluminum nanowires are expected to be used in advanced electronics such as gas sensors, devices that can detect biological signals (biomarkers), and optoelectronics, which involve the use of light.

The wires also have special qualities, such as a large surface area, good mechanical strength, and resistance to natural oxidation, which makes them last longer.

Professor Kimura said, “We were able to grow these metal nanowires using just three simple steps: coating a thin film on a base, shooting ion beams at it, and heating it. This could be a key step in producing high-performance devices on a large scale.”

This breakthrough opens up new possibilities for making nanowires from other metals too, which could further improve the technology of future electronic devices.