Scientists at Penn State have made a significant breakthrough in the field of thermoelectric generators, which can turn waste heat into clean energy.

This new development could make these devices as efficient as other renewable energy sources like solar power.

Thermoelectric generators work by converting temperature differences into electricity.

For example, when placed near a heat source, such as a steam pipe in a power plant, these devices generate an electric current as charge carriers like electrons move from the hot side to the cold side.

Currently, most commercially available thermoelectric devices are only 5% to 6% efficient.

However, the Penn State team has developed a new prototype that achieves a 15% conversion efficiency—more than double the current standard.

This improvement means that either the size of the devices can be reduced by 200% while maintaining the same energy output, or the same-sized device could produce 200% more energy.

The key to this breakthrough lies in a new class of materials called high-entropy half-Heusler alloys.

Traditional thermoelectric materials, like half-Heusler alloys, are already known for their ability to generate power at medium-high temperatures.

These materials are typically made from three metallic elements, sometimes with small amounts of other materials added to improve performance.

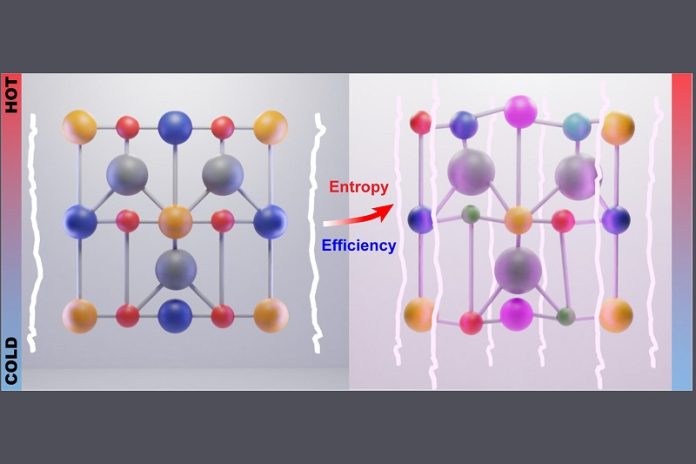

In their new approach, the Penn State researchers used high-entropy materials, which contain at least five principal elements in a single crystalline structure.

These materials have similar properties to traditional half-Heusler alloys but are enhanced.

The extra elements make the crystalline structure more disordered, which slows down the movement of charge carriers and lowers the material’s thermal conductivity.

At the same time, the material’s power factor, which measures how efficiently it converts power into useful work, remains high.

This combination of low thermal conductivity and high power factor leads to a significant increase in the material’s figure of merit, a measure of its effectiveness as a thermoelectric material.

The new material achieved a record figure of merit of 1.50 at a temperature change of 1,060 degrees Kelvin, which is about 1,448 degrees Fahrenheit. This is a 50% improvement over current cutting-edge materials.

The implications of this breakthrough are vast. More efficient thermoelectric generators could be used to recover waste heat in industrial settings, reducing fossil fuel consumption and cutting emissions.

Additionally, because these devices have no moving parts and produce no chemical reactions, they offer a promising source of clean energy.

The researchers are hopeful that by applying this high-entropy approach to other types of thermoelectric materials, they can push conversion efficiencies even higher, potentially reaching 20% or more.

If successful, thermoelectric generators could become a competitive alternative to solar energy and other renewable energy technologies.