Scientists at the Department of Energy’s Oak Ridge National Laboratory (ORNL) are making exciting strides toward the future of electric vehicle batteries.

By creating a new type of thin, flexible film, they’re working on solid-state batteries that could significantly increase how much energy these batteries can store—potentially doubling it.

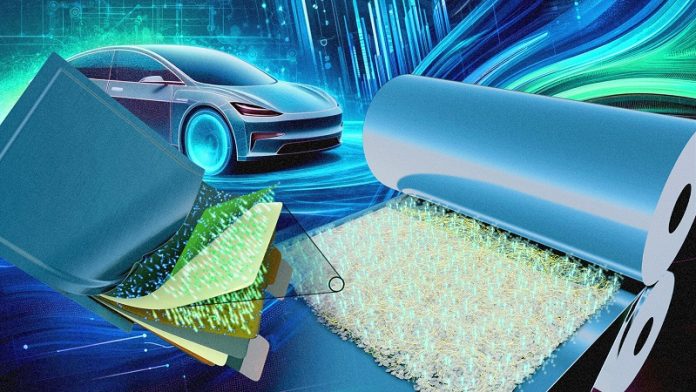

The key innovation lies in developing thin sheets of solid-state electrolytes.

These sheets are strong yet flexible, and they’re designed to improve the safety, performance, and energy capacity of batteries used in electric vehicles, laptops, and smartphones.

Today’s batteries often use liquid electrolytes, which can be dangerous because they’re flammable, chemically reactive, and prone to leaking.

In contrast, solid-state electrolytes don’t have these risks. They’re also expected to perform better and store more energy, meaning devices could run much longer on a single charge.

ORNL’s new electrolyte sheets could hold up to 500 watt-hours of energy per kilogram—twice as much as current batteries.

This advancement is significant because it could allow electric vehicles to travel much farther on a single charge.

The research team focused on finding the perfect thickness for these electrolyte sheets. They needed to be thin enough to conduct electricity well but also strong enough to hold up in a battery.

The scientists achieved this balance by using a special polymer binder to create the film.

Polymers are large molecules made up of repeating units, and in this case, the binder’s job is to hold the electrolyte material together in a thin film. The challenge is that the polymer itself doesn’t conduct electricity, so they needed to use as little as possible.

However, using too little would make the film too weak to be practical. The team discovered that using a heavier polymer binder with longer molecular chains provided the best results. These binders created stronger films with fewer amounts, which is ideal for boosting the battery’s performance.

The researchers also focused on sulfide solid-state electrolytes, which have a conductivity similar to liquid electrolytes currently used in lithium-ion batteries. This means they allow lithium ions to move efficiently back and forth during charging and discharging, which is critical for the battery’s function.

To ensure their films were up to the task, the ORNL team used a variety of advanced techniques to examine the materials. For instance, they used scanning electron microscopy and X-ray spectroscopy to study the films at a microscopic level, looking at how the materials were structured and how they performed under different conditions.

The research team is now working to integrate these thin films into complete batteries and test them in real-world conditions.

They’re also expanding their lab space at ORNL to include specialized areas for working with the sulfide materials, which require very low humidity environments to avoid contamination.

This work is just the beginning of what could be a major leap forward in battery technology.

By collaborating with other researchers and institutions, the ORNL team hopes to bring these next-generation solid-state batteries closer to becoming a reality, paving the way for safer, more efficient, and longer-lasting power sources for electric vehicles and many other devices.