A groundbreaking 3D printing method developed by researchers from the National University of Singapore (NUS) promises to change the future of electronics.

This new technique, called tension-driven CHARM3D, allows for the creation of three-dimensional (3D), self-healing electronic circuits without the need for support materials or external pressure.

Traditionally, circuit boards are flat, but 3D circuitry enables components to be stacked vertically, reducing the space required for devices.

This advancement could lead to more compact and efficient electronics, including wearable sensors and wireless communication systems.

Led by Associate Professor Benjamin Tee, the NUS team used a special metal called Field’s metal to demonstrate the capabilities of CHARM3D.

Field’s metal, an alloy of indium, bismuth, and tin, has a low melting point, high electrical conductivity, and low toxicity.

It solidifies quickly, allowing the printing process to be faster and more precise compared to traditional methods.

One major advantage of CHARM3D is its ability to create smooth and uniform microwires with adjustable widths of 100 to 300 microns—about the width of one to three human hairs.

This technique avoids the issues of beading and uneven surfaces seen in other 3D printing methods, enabling faster printing speeds of up to 100 millimeters per second.

CHARM3D’s innovative approach has several benefits. It does not require post-treatment steps and can fabricate complex free-standing 3D structures, such as vertical letters, cubic frameworks, and scalable helixes.

These structures also have self-healing capabilities, meaning they can recover from mechanical damage and are recyclable.

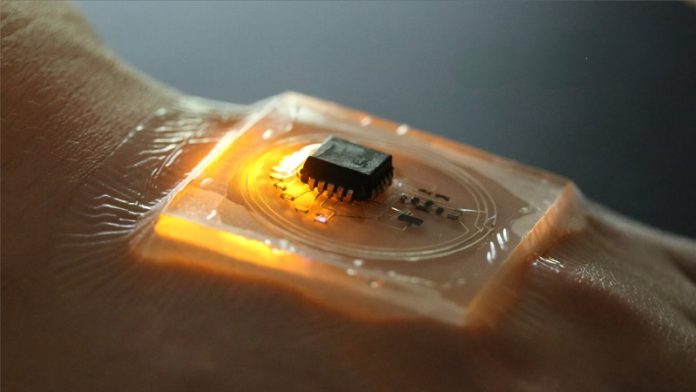

The researchers successfully used CHARM3D to design and create a 3D circuit for a wearable battery-free temperature sensor system, highlighting its potential for various applications in health care.

Traditional hospital equipment, like electrocardiograms and pulse oximeters, require skin contact, which can cause discomfort and infection risks.

With CHARM3D, contact-free sensors can be integrated into smart clothing and antennas, providing continuous and accurate health monitoring in hospitals, assisted-living facilities, or home settings.

CHARM3D also enables the creation of 3D antennas and electromagnetic metamaterial sensors, improving signal sensing and processing.

This leads to better communication systems, more accurate medical imaging, such as early tumor detection, and advanced security applications, like detecting hidden devices.

The team’s findings were published in Nature Electronics on July 25, 2024.

The researchers believe that this technique can be extended to other types of metals and structural applications, with potential for commercialization.

In summary, the CHARM3D technique developed by NUS researchers represents a major leap in 3D printing technology, offering faster, simpler, and more accurate manufacturing of advanced electronic circuits with wide-ranging applications in health care and beyond.

Source: National University of Singapore.