Yuichi Hirose has a unique dream: to create a machine that can knit furniture.

Imagine having a machine that doesn’t just knit fabric but can create solid objects like chairs and tables from yarn.

If you get tired of your love seat, you could simply unravel it and knit yourself a new ottoman.

Hirose, a robotics Ph.D. student at Carnegie Mellon University (CMU), calls this technique “solid knitting.”

After more than a decade of development, Hirose, working with a research team led by Associate Professor James McCann, has turned this dream into reality.

“My dream is to have these solid knitting machines everywhere in the world,” Hirose said.

Hirose’s inspiration came from a software project by McCann that made it easier to reprogram commercial knitting machines. This software allowed for the creation of customized 3D knitted pieces, although these were hollow shapes that could be stuffed rather than solid objects. The two began collaborating to make solid knitting possible.

By 2020, Hirose had built a prototype of his knitting machine, but the COVID-19 pandemic delayed further work. In 2022, Hirose joined the CMU Textiles Lab and the Ph.D. program in robotics. The team presented their solid knitting research and prototype machine at SIGGRAPH 2024, an annual conference on computer graphics, where they received an honorable mention.

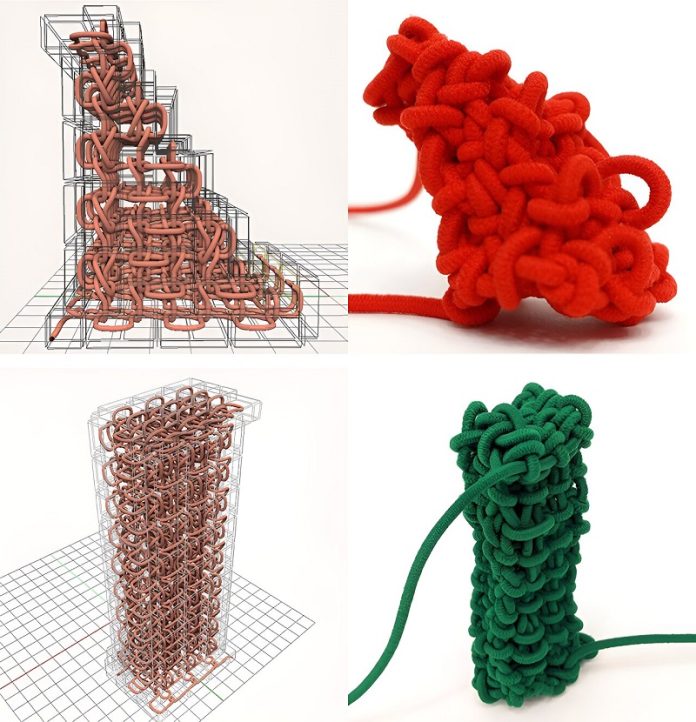

The prototype machine, about the size of a clothes dryer, is currently limited in the shapes and sizes it can produce. It can create triangular or rectangular prisms of various lengths. The machine uses elastic cord as yarn, resulting in surprisingly firm knitted objects. “It feels sort of like a stack of felt or the sole of a shoe,” McCann said.

Though the current machine is limited, the technique can also be used to hand-knit larger and more complex shapes, such as a pair of sandals. Hirose plans to take future research in two directions: building a larger machine for producing furniture and making a smaller machine for precise objects.

“We hope that other people out there are going to build their own solid knitting machines and come up with ideas we haven’t yet explored,” McCann said.

The research team also included Angelica Bonilla Fominaya, who produced art pieces using the technique, and Mark Gillespie, who developed 3D visualization software to aid in the design process. More information is available on the project’s website, including instructions and videos for hand knitting solid objects.

Solid knitting is similar to 3D printing. Just as 3D printers build objects layer by layer, solid knitting builds shapes by adding knitted layer after knitted layer. Instead of using glue or melted plastic, each new layer is stitched to the previous one.

Hirose first got the idea in 2012 while studying digital fabrication at Keio University in Japan. Inspired by a project called Claytronics, which involved modular robots creating various shapes, Hirose sought a more durable and reconfigurable solution. This led to his concept of solid knitting.

After completing his master’s degree and working for a few years, Hirose secured grants, quit his job, and began building the solid knitting machine in 2018. Using rows of latch needles, similar to commercial knitting machines, his machine manipulates yarn to create solid objects.

Hirose’s vision of knitting solid furniture may soon become a reality, bringing a new level of versatility and creativity to home furnishings.