Researchers at the University of Maryland have made an exciting breakthrough by genetically modifying poplar trees to produce high-performance wood without the need for harmful chemicals or energy-intensive processing.

This new type of wood could help reduce carbon emissions and serve as a more sustainable alternative to traditional building materials like steel, cement, glass, and plastic.

Engineered wood, made from regular wood, is often praised as a renewable resource that can store carbon for longer periods than untreated wood.

However, the current methods for creating engineered wood involve using volatile chemicals and large amounts of energy, which can generate significant waste.

To overcome these challenges, the researchers developed a way to grow poplar trees that are ready for engineering without any additional processing.

The team, led by Yiping Qi, a professor in the Department of Plant Science and Landscape Architecture at the University of Maryland, used a technique called base editing to modify a specific gene in the poplar trees.

By knocking out a key gene called 4CL1, they were able to grow trees with 12.8% less lignin than normal poplar trees.

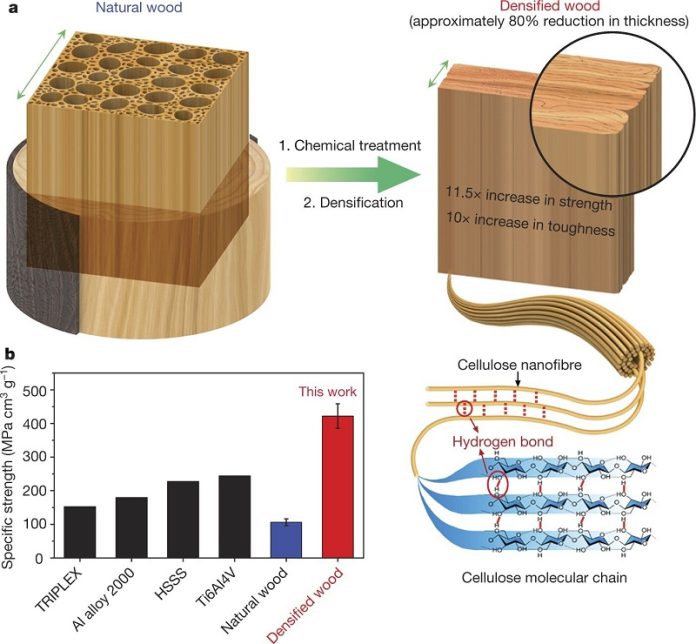

Lignin is a natural component of wood that needs to be removed to give the wood structural properties like increased strength or UV resistance, allowing it to be used as a substitute for materials like steel or concrete.

Traditionally, lignin is removed from wood using chemicals, but this new method eliminates the need for those chemicals, making the process more environmentally friendly.

The researchers grew their genetically modified trees alongside regular poplar trees in a greenhouse for six months and found no differences in growth rates or structure between the two.

To test the strength and viability of their modified wood, the team compressed it to produce high-strength wood similar to particle board, which is commonly used in furniture.

Compressed wood is made by soaking the wood in water and then hot-pressing it until it is nearly one-fifth of its original thickness. This process increases the density and strength of the wood.

The results were impressive. The compressed genetically modified wood was as strong as wood that had been chemically treated to remove lignin, and it performed on par with untreated natural wood.

In fact, the tensile strength of the compressed genetically modified wood was comparable to that of aluminum alloy 6061, a common material used in construction.

This innovative approach to wood production could lead to a more sustainable way of manufacturing building materials, helping to reduce the environmental impact of construction and play a significant role in the fight against climate change.

The research was published in the journal Matter on August 12, 2024.