Researchers at the University of Massachusetts Amherst have discovered a new way to help robots work together more effectively.

This breakthrough could lead to faster task completion in industries like manufacturing, agriculture, and warehouse automation.

The study was recognized as a finalist for the Best Paper Award on Multi-Robot Systems at the 2024 IEEE International Conference on Robotics and Automation.

Traditionally, there has been a debate over whether it’s better to build a single, powerful robot that can do all jobs or create teams of robots that can collaborate. Hao Zhang, an associate professor at UMass Amherst and director of the Human-Centered Robotics Lab, believes the latter is the key.

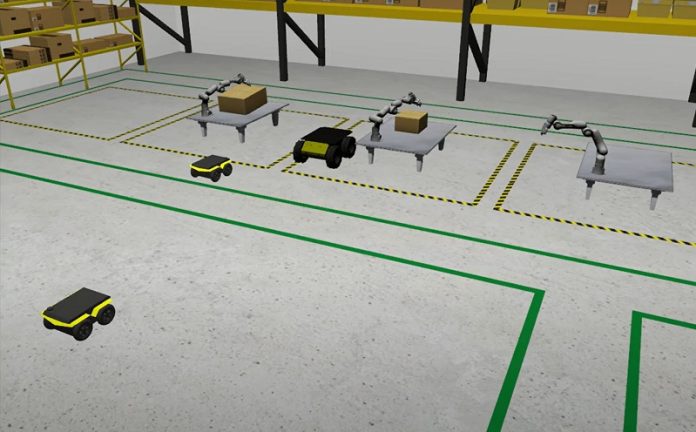

He explains that while having a team of robots can be more cost-effective, the challenge lies in coordinating these diverse robots—some may be mobile, others stationary, some might lift heavy loads, while others handle smaller tasks.

To tackle this problem, Zhang and his team developed a new scheduling method called Learning for Voluntary Waiting and Subteaming (LVWS). This method teaches robots not only to work together on big tasks but also to wait voluntarily when it’s beneficial for the team.

For example, imagine a situation where three robots need to move boxes. Two small robots can each lift four pounds, and a larger robot can lift ten pounds. If there’s a seven-pound box to move and one of the small robots is busy, the LVWS method would have the other small robot wait for its partner rather than use the big robot. This way, the big robot is free to handle a larger task that only it can do.

The team tested this approach by running computer simulations where six robots had to complete 18 tasks. They compared their new method with four existing ones. The goal was to see how close each method came to the perfect, fastest way to complete all the tasks, known as the “optimal solution.”

The LVWS method was almost as good as the perfect solution, missing it by just 0.8%. The other methods were less accurate, ranging from 11.8% to 23% off. This shows that the LVWS method allows robots to complete tasks faster and more efficiently than other methods.

The research team also tested their method on a larger scale, involving 100 tasks. Even when it was impossible to calculate the perfect solution quickly, their method still completed the tasks faster than the others, proving its effectiveness in complex situations.

Zhang believes that this research could significantly impact industries where large-scale robot teamwork is needed. For instance, while a single robot might be better for small, confined spaces like homes, teams of specialized robots could be the future of large industrial environments.

This new approach could be a major step forward in the development of automated robot teams, making them more effective and adaptable in various settings.