Imagine knowing your milk has gone bad without even opening the fridge.

This might sound like science fiction, but it’s a glimpse into the future made possible by a technology called printed electronics.

This technology involves creating electronic circuits on sheets that are thin, flexible, and even bendable.

Already, printed electronics are being used in a variety of applications, from solar cells on vehicle roofs to flexible displays on smartphones.

Now, a groundbreaking discovery has the potential to take printed electronics to the next level.

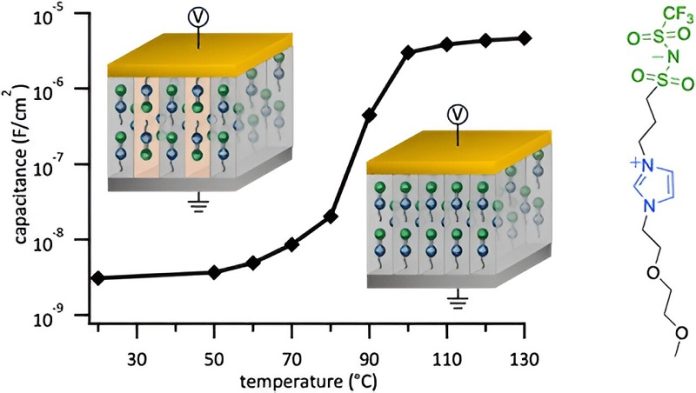

Researchers from Simon Fraser University (SFU) and the University of Saskatchewan (USask) have developed a new material that can store up to 1,000 times more charge than current printed electronics.

This breakthrough could bring the concept of the Internet of Things (IoT) closer to reality.

The Internet of Things is an idea that involves embedding electronics into everyday objects so they can communicate with each other and with our devices, like smartphones and computers.

For example, with IoT, your milk carton could send a signal to your phone when the milk is about to spoil.

This kind of technology could greatly reduce food waste by ensuring that we only consume fresh products and by improving efficiency across the entire food supply chain.

However, making the Internet of Things a reality requires advanced electronics that can handle complex operations, such as functioning in both positive and negative voltage modes.

This is where the new material developed by Loren Kaake, an associate professor in SFU’s Department of Chemistry, and his team shines.

“This material really stands out because it outperforms even the most cutting-edge materials currently available,” Kaake explained. “It makes a strong case for the commercial potential of printed electronics.”

The research team made use of the Canadian Light Source (CLS) at the University of Saskatchewan to study and enhance the performance of their new material.

The CLS is a facility that produces intensely bright synchrotron light, which allows scientists to examine materials at the nanoscale, or the level of individual atoms and molecules.

“The synchrotron light helped us understand the tiny structures within our material, showing us what works well and what needs improvement,” Kaake said. “The data we gathered at the CLS provides insights into how we can further engineer the material to improve its performance.”

The team published their findings in the journal ACS Applied Materials and Interfaces, and they believe this new material could be available on the market in about seven years.

When the time comes, the material could be easily integrated into the production of printed electronics, serving as a “plug and play” replacement that enhances the capabilities of these devices.

“Developing new materials is crucial because even the best applications can benefit from better materials,” Kaake noted. “If our material is compatible with future electronic printing techniques, it could be readily adopted for a wide range of uses.”

This new material represents a significant step forward in the field of printed electronics and the Internet of Things. As the technology continues to develop, we can expect to see more smart and connected devices in our everyday lives, making everything from monitoring food freshness to managing energy consumption more efficient and accessible.