A new technique developed by University of Houston professor Jiming Bao promises to improve thermal imaging and infrared thermography.

These techniques, which help visualize temperature distributions without direct contact, are vital in fields like medicine, police work, and the military.

Thermal cameras and infrared thermometers are sensitive tools that can measure temperature accurately from a distance.

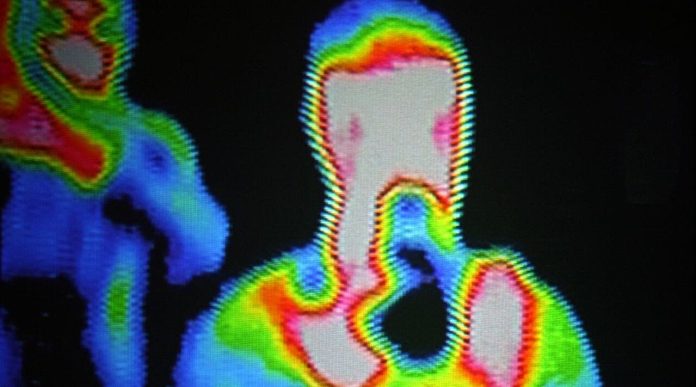

They detect infrared radiation, which is invisible to the human eye, and convert it into visible images.

These images use different colors to represent various temperatures, allowing users to see heat patterns and differences.

Thermal imaging and infrared thermography have many uses, including:

- Medical Diagnostics: Detecting inflammation and poor blood flow.

- Building Inspections: Finding heat loss, insulation issues, and water leaks.

- Military, Security, and Surveillance: Spotting people or animals in low visibility conditions.

- Mechanical Inspections: Identifying overheating machinery or electrical faults.

Both techniques are based on the principle of blackbody radiation.

Objects emit infrared radiation depending on their temperature, and by capturing this radiation, these tools provide valuable insights into the thermal properties and behaviors of various objects and environments.

Traditional thermal cameras and infrared thermometers face challenges in providing accurate readings because they rely on emissivity—a measure of how effectively an object emits thermal radiation. Emissivity varies with temperature, which can lead to inaccuracies.

Multi-spectral techniques, which measure infrared intensity at multiple wavelengths, try to address this but still depend on emissivity models.

Professor Bao’s new method, reported in the journal Device, uses a near-infrared spectrometer to measure the continuous spectrum of light and fits it using the ideal blackbody radiation formula.

This technique includes a simple calibration step to eliminate temperature- and wavelength-dependent emissivity, improving accuracy.

Bao demonstrated his technique by measuring the temperature of a heating stage with errors of less than 2°C.

He also measured the surface temperature gradient of a catalyst powder under laser heating.

Using the near-infrared spectrometer, thermal radiation from a hot target is collected with an optical fiber and recorded by a computer. The collected spectrum is then normalized using a system calibration response and fitted to determine the temperature accurately.

“This technique overcomes challenges faced by conventional thermal cameras and infrared thermometers due to the unknown emissivity of targets,” said Bao. “It reveals much higher surface temperatures of photothermal catalysts than those measured by a buried thermocouple under strong light illumination.”

Professor Bao’s new technique enhances the accuracy and effectiveness of thermal imaging and infrared thermography.

By overcoming the limitations of traditional methods, this advancement holds promise for improving applications in medical diagnostics, building inspections, military operations, and more.

This breakthrough not only provides more accurate temperature measurements but also opens up new possibilities for using thermal imaging in various fields.