Did you know that power plants, factories, and car engines waste a lot of energy as heat?

Imagine if we could capture that wasted heat and turn it back into electricity.

That’s what thermoelectric devices can do, but making them has been too expensive and complicated—until now.

Yanliang Zhang, a professor of Aerospace and Mechanical Engineering at the University of Notre Dame, along with a team of researchers from different institutions, has developed a new method to produce these devices.

Their breakthrough was recently published in the journal Energy & Environmental Science.

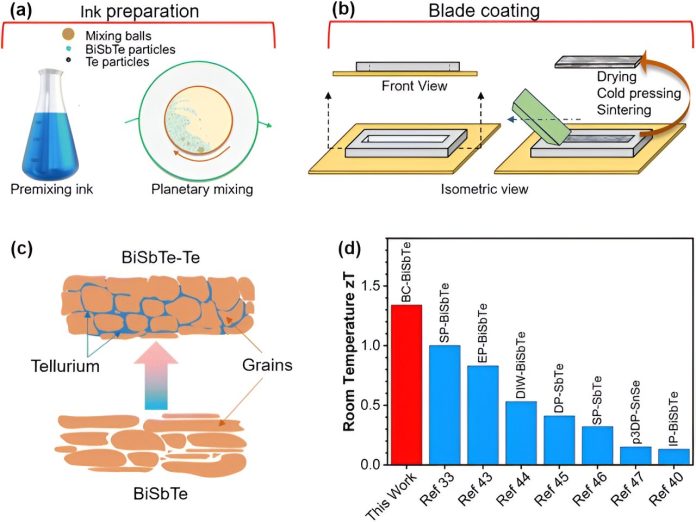

Zhang and his team have created a special ink-based manufacturing method that makes it possible to produce thermoelectric devices on a large scale and at a lower cost.

“Using our new ink recipe and processing technique, we’ve made a material that’s more efficient at turning waste heat into electricity than any previous ink-produced device,” Zhang explained.

“With this method, we can create devices in various sizes—from a thin film just a few microns thick to a larger device that can collect waste heat from a power plant.”

So, how do these thermoelectric devices work? They need a hot side and a cold side to function. Electric current should flow easily through the material, but heat should not. If heat flows too easily, it would eliminate the temperature difference needed for the device to work efficiently.

In the past, creating materials with these special properties involved labor-intensive and energy-consuming processes that weren’t uniform and scalable. But the new method developed by Zhang’s team changes all that.

Their “ink recipe” combines thermoelectric particles with a solvent and tellurium, an additive that reduces defects in the material and helps solidify the final composite. This ink-based technique allows the team to have more control over the material’s microstructure and final 3D shape compared to older methods.

Interestingly, thermoelectric devices don’t just convert waste heat into electricity. They can also be used for cooling without emissions or refrigerants if you provide them with electric power.

Zhang believes this discovery has significant potential. “We think our findings are very promising for recovering waste heat, improving energy efficiency, reducing CO2 emissions, and providing environmentally friendly solid-state cooling and refrigeration,” he said.

This new method could change the way we think about energy and waste. By capturing and reusing wasted heat, we can make our power plants, factories, and car engines more efficient and less harmful to the environment. Plus, the ability to cool without using harmful refrigerants could help reduce global warming.

In simple terms, Zhang and his team have found a way to turn wasted heat into valuable electricity using a new and improved manufacturing process. This could lead to more efficient energy use and a cleaner, cooler planet.