Carbon dioxide (CO2) is a major problem for our environment, leaking from industrial activities and causing harmful changes to Earth’s climate.

But what if we could turn this harmful gas into something useful?

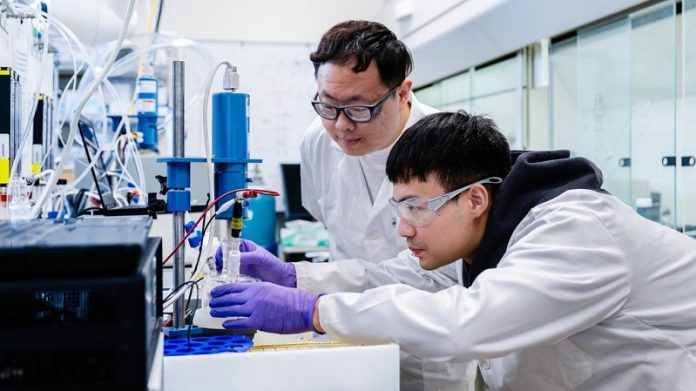

Scientists from Argonne National Laboratory, the University of Chicago, Northern Illinois University, and Valparaiso University have found a way to do just that.

These researchers have developed a special type of catalyst that can efficiently convert CO2 into useful chemicals like ethanol, acetic acid, and formic acid.

These chemicals are among the most commonly produced in the United States and are used in many everyday products.

For instance, ethanol is a key ingredient in numerous household items and is added to almost all gasoline in the U.S.

“If fully developed, our catalysts could convert the CO2 produced at various industrial sources to valuable chemicals,” said Di-Jia Liu, a senior chemist at Argonne and a senior scientist at the University of Chicago.

This means that CO2 from fossil fuel power plants, bio-fermentation, and waste treatment facilities could be transformed into useful products instead of polluting the atmosphere.

The team uses a method called electrocatalytic conversion, where electricity drives the conversion of CO2 over a catalyst. The catalysts they developed are based on tin metal placed on a carbon support.

By changing the size of the tin—from single atoms to tiny clusters and larger nano-crystals—the scientists can control the conversion process to produce acetic acid, ethanol, or formic acid.

Impressively, the selectivity for each of these chemicals is 90% or higher, meaning the process is highly efficient.

“Our finding of a changing reaction path by the catalyst size is unprecedented,” Liu said, highlighting the novelty of their discovery.

The reaction does require electricity, so to make the technology fully eco-friendly, the team aims to use locally generated electricity from renewable sources like wind and solar power. This would involve integrating the new catalysts into a low-temperature electrolyzer, which uses electricity to carry out the CO2 conversion.

These electrolyzers operate at near ambient temperature and pressure, making them ideal for use with intermittent renewable energy sources. They can start and stop quickly, matching the variable supply of wind and solar power.

Liu noted that producing only the chemicals needed at the site of CO2 production could reduce transportation and storage costs. “It would truly be a win-win situation for local adopters of our technology,” he said.

This groundbreaking research benefited from the use of two facilities at Argonne National Laboratory: the Advanced Photon Source and the Center for Nanoscale Materials. The collaboration and resources provided by these facilities played a crucial role in the success of the study.

In summary, this new catalyst technology has the potential to turn CO2 from industrial pollution into valuable chemicals, offering a promising solution to both reduce greenhouse gas emissions and create useful products. It’s a significant step towards a greener and more sustainable future.