Fusion energy promises to be a powerful and clean energy source, but controlling the intense heat in fusion reactors is a major challenge.

Researchers at the Princeton Plasma Physics Laboratory (PPPL) are exploring innovative ways to manage this heat, including using liquid metals like lithium.

Fusion reactors need to keep their plasma hot enough to generate power, but not so hot that it damages the reactor’s interior.

One solution involves using liquid lithium to absorb excess heat and protect the reactor’s components from particle bombardment.

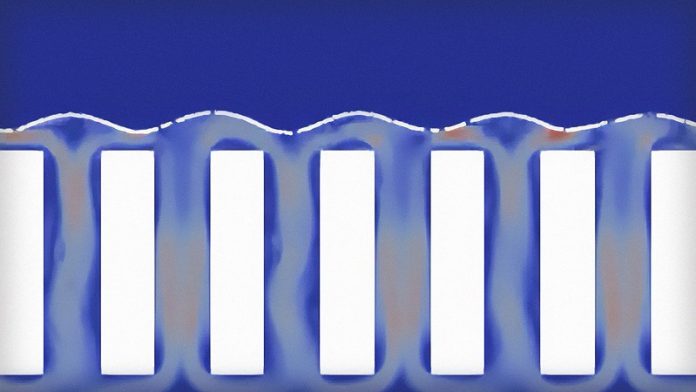

The PPPL team, led by Egemen Kolemen, is investigating how liquid lithium can flow up and down slats in the reactor, drawing away heat and shielding the reactor from damage.

“The best design for a commercial fusion reactor is a compact one,” said Kolemen. “But compact reactors face big challenges with heat and particle bombardment. Currently, no solid materials can handle these conditions.

Flowing liquid metals might solve these problems.”

In their design, liquid lithium briefly touches the plasma’s heat at the top of a slat, then flows down a channel between slats to cool off. This cycle repeats, with the lithium heating up and cooling down in a continuous loop.

This method reduces the risk of overheating and evaporation, which were issues in past designs where liquid metal stayed in contact with the plasma for too long.

Experiments with a prototype of this cooling system were successful. “We replicated the flow loops around the slats, which is how the system works,” said Francisco Saenz, a graduate student at Princeton and co-author of the study. “Cool liquid metal quickly replaces the heated metal, preventing it from getting too hot.”

Using galinstan—a mix of gallium, indium, and tin—instead of lithium for testing, the researchers found that the electrical conductivity of galinstan is similar to that of lithium. This allowed them to study how the liquid metal would behave under strong magnetic fields, like those in a fusion reactor.

They increased the electric current applied to the liquid in steps to see how it affected flow speed and uniformity. They achieved their target speed without splashing, showing that their design worked as intended.

Princeton University graduate student Brian Wynne is excited about future improvements. “There’s still more work to do,” he said. “We need to optimize the slat geometry, possibly by reducing slat width and rounding edges to create a smoother surface for better heat absorption.”

Future prototypes might use 3D-printed tungsten slats, a highly durable metal well-suited for components exposed to plasma. The current prototype is a closed system, but future designs will explore systems for flowing lithium in and out of the reactor.

This innovative approach to controlling fusion heat could pave the way for more efficient and effective fusion reactors, bringing us closer to realizing the dream of sustainable fusion energy.