Imagine a crew of astronauts on their way to Mars. About 140 million miles from Earth, they find a cracked O-ring in their spacecraft.

Instead of relying on a limited supply of spare parts, what if they could just print any part they needed right there?

A team of researchers from Berkeley, led by Ph.D. student Taylor Waddell, is working to make this a reality.

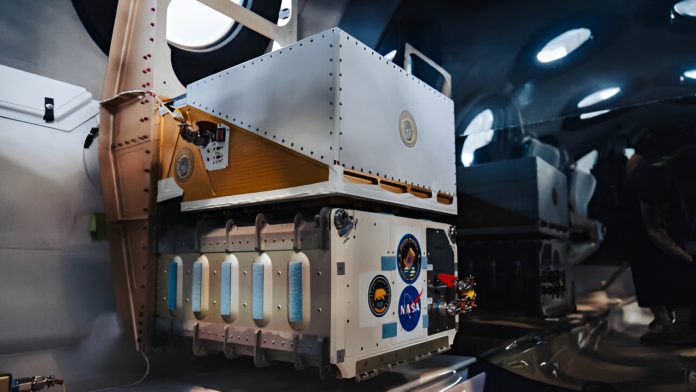

On June 8, they sent their 3D printing technology to space for the first time as part of the Virgin Galactic 07 mission.

Their next-generation microgravity printer, called SpaceCAL, spent 140 seconds in suborbital space on the VSS Unity space plane. During that short time, it printed and post-processed four test parts, including small models of space shuttles and benchy figurines from a liquid plastic called PEGDA.

“SpaceCAL performed well in microgravity tests during parabolic flights, but this mission was its ultimate test,” said Waddell. “This mission allowed us to prove that this 3D printing technology is ready for space travel.”

He added, “We hope it will someday be used to make everything from spacecraft parts and tools to new contact lenses and dental crowns for astronauts.”

3D printing, also known as additive manufacturing, has come a long way since it was first patented in the 1980s. Hayden Taylor, an associate professor of mechanical engineering, led a team of UC Berkeley and Lawrence Livermore National Laboratory (LLNL) researchers that invented Computed Axial Lithography (CAL) technology in 2017.

This new type of additive manufacturing uses light to shape solid objects from a viscous liquid, allowing for a wider range of printable shapes and significantly increasing the speed of printing. It also works well in microgravity, making it perfect for space exploration.

CAL technology is what brought Waddell to Berkeley to pursue his Ph.D. in mechanical engineering. As an undergraduate at the University of Wisconsin, Madison, and a Pathways Engineer at NASA, Waddell became fascinated by 3D printing and its ability to turn ideas into physical forms quickly and affordably.

After learning about CAL, he contacted Taylor and soon joined his lab at Berkeley. There, he spent countless hours working on ways to use this technology for the greater good.

CAL stands out from other 3D printing technologies because of its incredible speed—it can create parts in as little as 20 seconds. This speed is crucial for astronauts who need to print parts quickly in an emergency, potentially reducing the need to carry thousands of spare parts on long space missions.

“You can reduce the weight of supplies, make missions go faster, and lower risks by bringing manufacturing technologies with you,” said Waddell.

CAL’s ability to print well in microgravity also allows engineers to explore the limits of 3D printing in space.

“With CAL, we showed that we can print parts in microgravity that aren’t possible on Earth,” said Waddell.

CAL has already proven it can print with more than 60 different materials on Earth, such as silicones, glass composites, and biomaterials. This versatility could be useful for both the spacecraft and the crew.

“If your spacecraft is breaking down, you can print O-rings, mechanical mounts, or tools,” said Waddell. “CAL can also repair the crew by printing dental replacements, skin grafts, or emergency medical supplies personalized for astronauts.”

In the future, CAL might be used to print even more sophisticated parts, such as human organs. LLNL has received a grant from NASA to test this technology on the International Space Station.

“They’re going to do bioprinting on the Space Station,” said Waddell. “The long-term goal is to print organs in space and bring them back to Earth.”

Next, Waddell and his colleagues hope to work with NASA to develop and validate a single object that could support crew health and wellness, like a dental crown for an astronaut or a surgical wound closure tool.

“These experiments aim to push technology for everyone’s benefit,” said Waddell. “Even though it’s for space, it can also help people on Earth.”

This project was made possible by the support of many student researchers and the guidance of Hayden Taylor. Virgin Galactic also played a crucial role in bringing this project to space.

“The team at Virgin Galactic helped us every step of the way, especially during the week preparing for the rocket launch,” said Waddell. “There were a lot of excellent engineers and passionate people who wanted to make sure we were successful.”

Source: UC Berkeley.