In the search for better batteries, researchers at Pohang University of Science and Technology (POSTECH) have made a significant breakthrough with solid-state batteries.

These batteries use solid electrolytes instead of liquid ones, making them safer and more powerful.

However, they often face issues with contamination, which the POSTECH team has now addressed in a groundbreaking way.

Led by Professor Byoungwoo Kang and Dr. Abin Kim from the Department of Materials Science and Engineering, the team has developed a special solid electrolyte with unique properties.

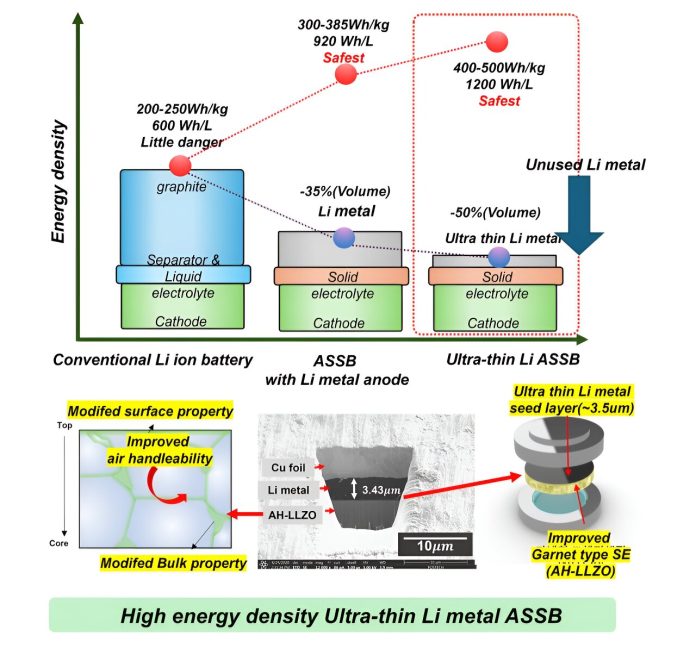

This new material allows for the creation of ultra-thin, highly stable, and energy-dense lithium metal solid-state batteries. Their findings were published in the journal ACS Energy Letters.

Solid-state batteries are seen as the future of battery technology due to their enhanced energy density and safety.

One of the most promising materials for these batteries is a type of solid electrolyte known as garnet-type oxide (Li7La3Zr2O12, or LLZO).

This material has high ionic conductivity, which is excellent for battery performance. However, when LLZO is exposed to air, it forms a contamination layer (Li2CO3) on its surface, which hampers its effectiveness by acting as a barrier and reducing contact with the lithium metal anode.

Many current solutions involve coating the LLZO surface or using additional chemical or heat treatments to remove this contamination.

However, these methods are not perfect because the contamination can reoccur once the LLZO is exposed to air again.

The POSTECH team took a different approach by focusing on improving the LLZO itself rather than adding extra steps. They developed a new type of LLZO, called air-handleable LLZO (AH-LLZO), which enhances the surface and internal properties of the material, preventing the contamination layer from forming in the first place.

Their experiments showed that the new garnet-type solid electrolyte created a hydrophobic compound (Li-Al-O) on both the surface and inside the material. This compound prevents the contamination layer from reacting with moisture in the air and spreading.

This improvement in the material’s properties allowed the researchers to create ultra-thin lithium metal layers, making the batteries about one-tenth the thickness of a human hair (~3.43 μm).

This innovation has several significant benefits. It allows for a major reduction in the amount of lithium metal used, reducing the overall weight and volume of the batteries while dramatically improving their energy density.

Additionally, the new material can be handled and stored in air without special facilities, simplifying the manufacturing process and making it more practical.

Professor Byoungwoo Kang stated, “We have solved the problem of LLZO’s inherent contaminant layer without the need for a post-processing step. We will continue to work on ultra-thin lithium metal solid-state batteries that can achieve high safety and high energy density.”

This breakthrough represents a significant step forward in battery technology, making future batteries safer, more efficient, and easier to produce.