Chemists have discovered new details about the reversible assembly and disassembly of a platinum catalyst.

This new understanding could provide insights into the catalyst’s stability and potential for reuse.

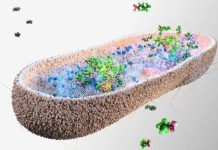

The study, published in the journal Nanoscale, revealed how single platinum atoms on a cerium oxide support come together to form active catalytic nanoparticles during a reaction, and then surprisingly break apart once the reaction stops.

This reversible process could help maintain the catalyst’s long-term stability.

“Such reversible fragmentation of a platinum nanocatalyst on cerium oxide could be potentially useful for controlling the catalyst’s long-term stability,” said Anatoly Frenkel, a chemist at Brookhaven Lab and professor at Stony Brook University who led the research.

When the platinum atoms return to their original positions, they can be reused to form active catalytic particles again.

This fragmentation prevents the active particles from fusing together permanently, a common issue that deactivates many nanoparticle catalysts.

“Part of the definition of a catalyst is that it helps disassemble and reassemble reacting molecules to form new products,” Frenkel noted. “But it was shocking to see a catalyst that also assembles and disassembles itself in the process.”

During their study, the researchers observed the nanoparticles forming as single platinum atoms aggregated on the cerium oxide surface at 572 degrees Fahrenheit (300 degrees Celsius), the temperature of the reaction they were studying.

Once the reaction stopped and the temperature dropped, the particles began to fragment back into single atoms.

The team proposed that carbon monoxide, a product of the reaction, played a key role in this fragmentation. Carbon monoxide molecules, which have strong repulsive interactions, stayed on the platinum atoms once the reaction cooled.

These molecules, crowding together, repelled each other and pulled the least tightly bound platinum atoms from the nanoparticles onto the cerium oxide support.

To understand this process, the scientists used a combination of atomic-level spectroscopic and imaging techniques. They used bright X-rays at the National Synchrotron Light Source-II to study the catalyst at different temperatures and stages of the reaction.

This technique provided insights into the neighbors of the platinum atoms, whether oxygen, carbon monoxide, or other platinum atoms.

However, this technique only provided average information. To get more detailed insights, the researchers used infrared spectroscopy, which showed the presence of two distinct groups—single platinum atoms and platinum nanoparticles.

They used this method to track how these groups changed as the reaction progressed.

Electron microscopy, performed at Brookhaven’s Center for Functional Nanomaterials, produced images showing both single atoms and nanoparticles. Before the catalyst was activated, there were no nanoparticles, but after the reaction, both forms were present.

“These techniques together tell us that, once the reaction stops and the temperature drops, the nanoparticles have started to fragment into single atoms,” Frenkel said.

“Each measurement independently would not have given us enough data to understand what we are dealing with. We couldn’t have done this work without our collaborators and the capabilities at these DOE Office of Science user facilities.”

Understanding these changes during the reaction is crucial for comprehending how the catalyst works.

The nanoparticles created in this process have more defects compared to those synthesized by other methods. These defects might improve catalytic performance by making the catalyst more active.

“People try to design catalysts with these types of imperfections deliberately; our method incorporates strain naturally,” Frenkel explained. This strain could make it easier for the nanoparticles to disassemble and reassemble, enhancing their reusability.

This discovery offers exciting possibilities for developing more stable and recyclable catalysts, potentially revolutionizing how catalysts are used in various chemical reactions.