Researchers at Washington State University (WSU) have developed a new robotic gripper that can gently pick apples without damaging them.

This innovation is part of a robotic system aimed at helping Washington farmers with fruit picking and other farm tasks, addressing the ongoing labor shortages.

The WSU team recently shared their work at the IEEE 7th International Conference on Soft Robotics. Chris Ninatanta, a Ph.D. student in the WSU School of Mechanical and Materials Engineering and the lead author of the paper, hopes this project will make a significant difference.

“Labor shortages in Washington can be very hurtful to orchards,” Ninatanta said.

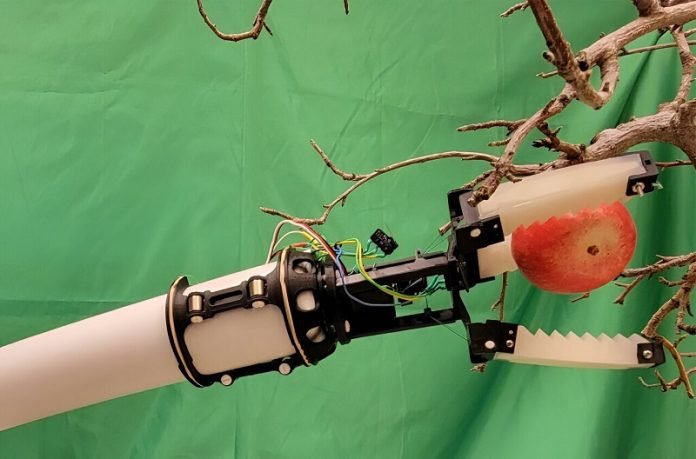

The gripper, weighing about two-thirds of a pound, uses three cables to move its 3D-printed plastic and silicone rubber-tipped fingers.

These fingers are designed to be gentle enough to avoid damaging the apples but strong enough to pick them off the tree.

At a production cost of about $30, the gripper includes a switch to grab and release the apple. It has successfully picked over 87.5% of apples in tests without causing any damage.

Ming Luo, an assistant professor in the School of Mechanical and Materials Engineering, and Manoj Kakee, a professor in Biosystems Engineering and the director of WSU’s Center for Precision & Automated Agricultural Systems, led this research.

“We’re always aiming to increase the success rate with new designs,” Luo said.

Washington state is the leading apple producer in the United States. In 2022, the apple industry added more than two billion dollars to the U.S. gross domestic product.

Farms in Washington hire anywhere from a dozen to hundreds of workers each year for various tasks, including pollination, pruning, thinning flowers, and harvesting fruit. However, with an aging workforce and fewer migrant workers, farmers have struggled to find enough workers during the harvest season.

In recent years, researchers have developed robotic apple harvesting systems, but these have been expensive and complicated to use. Ninatanta, who grew up in Yakima, Washington, picked fruit with his parents as a child.

When he started working on the robotic apple gripper, he had his parents film their work to help him design the gripper based on their techniques. “Some of the design for this is actually inspired by my parents,” he said.

The WSU team’s next step is to connect their lightweight gripper to a low-cost robot system they are developing. This robot arm, similar to the inflatable tube-people seen at car dealerships, is made of a soft fabric filled with air, but it is stiffer for better control.

Additionally, the researchers are working on adding an onboard camera to guide the arm and a gripper that can twist like a human hand to minimize damage to the apple stem. They plan to test this new system in their lab and on farms later this year.

Source: Washington State University.