A research team has made a breakthrough in improving the performance of solid oxide fuel cells (SOFCs).

They developed a catalyst coating that enhances SOFC efficiency by three times in just four minutes.

This study was led by Dr. Yoonseok Choi from the Korea Institute of Energy Research (KIER) along with Professor WooChul Jung from KAIST and Professor Beom-Kyung Park from Pusan National University.

SOFCs are gaining popularity as clean and efficient energy sources, essential for the hydrogen economy. These fuel cells can use various fuels like hydrogen, biogas, and natural gas, making them versatile and valuable for energy generation.

They also allow for combined heat and power generation, using the heat produced during the process.

The performance of SOFCs depends on the oxygen reduction reaction (ORR) at the air electrode, also known as the cathode. However, this reaction occurs slower at the cathode compared to the fuel electrode (anode), limiting the overall efficiency of the fuel cell.

Researchers are working on new materials for the air electrode to boost ORR activity, but these materials often lack chemical stability.

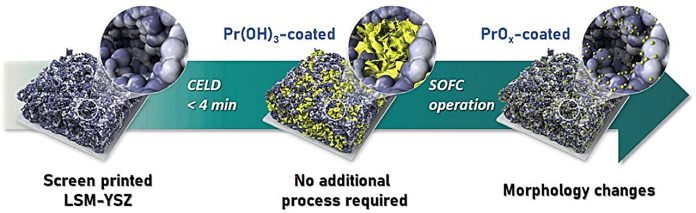

To address this, the research team focused on enhancing the LSM-YSZ composite electrode, a stable and widely used material in the industry. They developed a coating process using nanoscale praseodymium oxide (PrOx) catalysts. This coating significantly improves the oxygen reduction reaction, enhancing the overall performance of the SOFCs.

The team introduced an electrochemical deposition method that works at room temperature and normal pressure, making it simple and cost-effective. They immersed the composite electrode in a solution containing praseodymium ions and applied an electric current. This generated hydroxide ions at the electrode surface, which reacted with praseodymium ions to form a uniform coating on the electrode.

After drying, the coating turned into a stable oxide that effectively promotes the oxygen reduction reaction at high temperatures. The entire process takes only four minutes.

The research team also studied how the coated nano-catalyst improves surface oxygen exchange and ionic conduction. They provided evidence that this coating method can overcome the low reaction rate of the composite electrode.

By testing the catalyst-coated and conventional composite electrodes for over 400 hours, they found that the polarization resistance was reduced tenfold. The SOFC with the coated electrode showed a peak power density three times higher (from 142 mW/cm2 to 418 mW/cm2) at 650 degrees Celsius. This is the highest performance reported for SOFCs using LSM-YSZ composite electrodes.

Dr. Choi highlighted that their electrochemical deposition technique is a cost-effective addition to the existing SOFC manufacturing process.

This makes it suitable for industrial use, enhancing the applicability of oxide nano-catalysts in various energy conversion devices, including high-temperature electrolysis for hydrogen production.