A new wirelessly-powered 5G relay developed by scientists from Tokyo Tech could significantly advance smart factories.

By using a lower operating frequency for wireless power transfer (WPT), this innovative relay overcomes many current limitations, such as range and efficiency, allowing for a more versatile and widespread arrangement of sensors and transceivers in industrial settings.

Smart factories, part of the Industry 4.0 revolution, rely on the seamless flow of information.

This is made possible by installing wireless sensors and transceivers in robots, production machinery, and automatic vehicles.

5G networks are crucial for coordinating operations and communications between these devices. However, the challenge has been to provide power to these sensors and transceivers without cumbersome wires.

Wireless power transfer (WPT) is a solution to this challenge, but conventional WPT designs operating at 24 GHz face problems.

High-frequency beams must be very narrow to avoid energy losses, and power can only be transmitted if there is a clear line of sight between the WPT system and the target device.

This is particularly challenging in factories, where 5G relays extend the range of 5G base stations, requiring even greater reach.

To solve these problems, a research team from Tokyo Institute of Technology developed a novel 5G relay powered wirelessly at a lower frequency of 5.7 GHz.

Senior author and Associate Professor Atsushi Shirane explains, “By using 5.7 GHz as the WPT frequency, we can get wider coverage than conventional 24 GHz WPT systems, enabling a wider range of devices to operate simultaneously.”

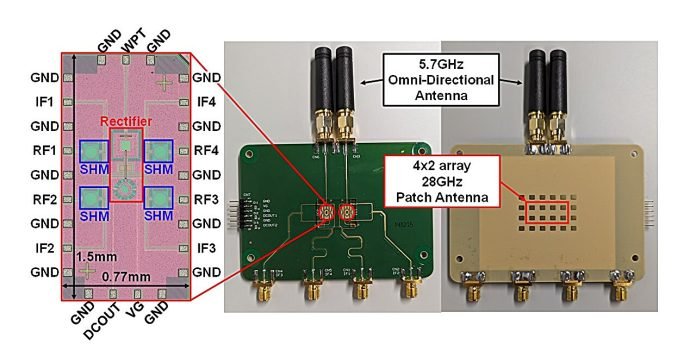

The proposed relay transceiver was created using Si CMOS 65nm chips and a 4×2 patch phased-array antenna board. It serves as an intermediary receiver and transmitter of 5G signals from a 5G base station or wireless devices. The key innovation is a rectifier-type mixer that performs 4th-order subharmonic mixing while also generating DC power.

This mixer uses the received 5.7 GHz WPT signal as a local signal. Together with multiplying circuits, phase shifters, and a power combiner, the mixer ‘down-converts’ a received 28 GHz signal into a 5.2 GHz signal. This 5.2 GHz signal is then internally amplified, up-converted back to 28 GHz, and retransmitted to its intended destination.

The system rectifies the 5.7 GHz WPT signal to produce DC power, which is managed by a dedicated power management unit. “Since the 5.7 GHz WPT signal has less path loss than the 24 GHz signal, more power can be obtained from a rectifier,” explains Shirane. “Additionally, the 5.7 GHz rectifier has a lower loss than 24 GHz rectifiers and can operate at a higher power conversion efficiency.”

Through experiments, the team demonstrated the capabilities of their relay. The relay chip, only 1.5 mm by 0.77 mm in size, can output a high power of 6.45 mW at an input power of 10.7 dBm. Multiple chips can be combined to achieve even higher power output.

This innovative 5.7 GHz WPT system offers many advantages, making it a promising development for the future of smart factories. By providing a reliable, wireless power source for sensors and transceivers, this technology could play a crucial role in advancing Industry 4.0.