Researchers at Princeton University and the Great Lakes Bioenergy Research Center have developed a model to map out the supply chain for second-generation biofuels in the Midwestern United States.

These advanced biofuels, derived from agricultural waste and non-food crops, could become a more sustainable alternative to fossil fuels like gasoline and diesel.

If managed well, they could even remove more greenhouse gases from the atmosphere than they emit.

Unlike first-generation biofuels, which are made from crops like corn and sugarcane that could otherwise be used for food, second-generation biofuels are produced from materials that don’t compete with food sources.

However, as a relatively new technology, their role in a low-carbon energy future is still uncertain.

Previous studies on biofuels have either focused on crop growth and land use or on the supply chain and refinery design.

The Princeton study combines both perspectives, providing a detailed look at the biofuel supply chain across eight Midwestern states. The findings were published on May 22 in Nature Energy.

“Our study brings together two different approaches to studying biofuels,” said Christos Maravelias, a professor at Princeton. “We used high-quality data to get a more complete view of these systems.”

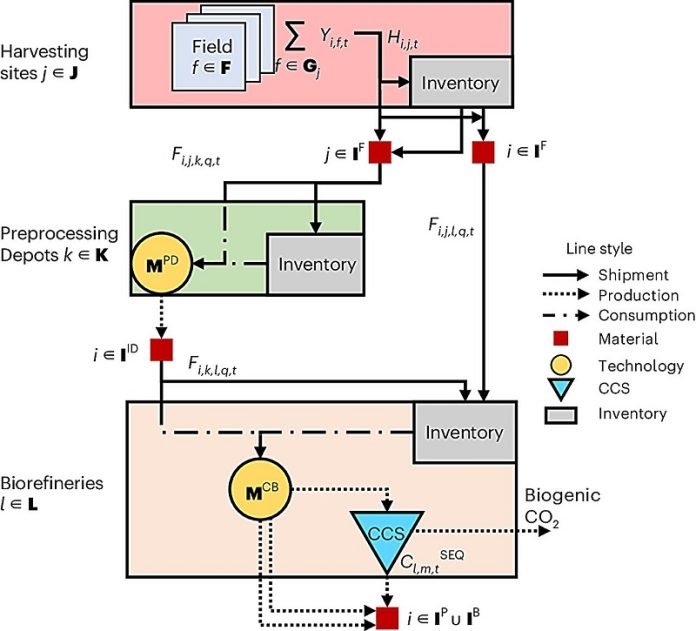

Biofuel supply chains are complex. Feedstocks must be grown and harvested from various lands, transported to refineries, and then converted into liquid biofuel. Different technologies can be used in this conversion, and any carbon emissions produced can be captured and sequestered offsite.

Decisions made at each step can result in different costs and emissions impacts, from the type of crop used to the distance between the field and the refinery.

“Even seemingly unrelated decisions, like the amount of incentive for carbon capture or the conversion technology used, can dramatically impact the design of a biofuel economy,” said Caleb Geissler, a graduate student at Princeton.

“The optimal design depends on the goals: how much biofuel to produce, at what cost, and with what carbon intensity.”

The researchers emphasized that their model isn’t specifically for decision-making but provides valuable insights into the economics and environmental impacts of a future bioeconomy.

Since second-generation biofuels haven’t yet achieved widespread commercialization, proactive research now can help ensure they are effectively integrated into future energy systems.

“The model considers all components of the system, allowing us to answer different questions,” Maravelias said. “We can identify the best way to produce a certain amount of biofuels while minimizing costs or environmental impacts or find a balance between the two.”

The team also examined the role of policy incentives in shaping the biofuels supply chain. For example, the 45Q tax credit for carbon capture, which offers $85 per ton of sequestered carbon, effectively incentivized carbon capture across the system.

However, lower tax credit values were insufficient to drive investment in carbon capture and sequestration.

The researchers modeled scenarios to minimize emissions from the entire supply chain, including transportation and electricity use. They found that incentives need to be at least $79 per ton to encourage carbon capture at refineries.

Below that, reducing transportation emissions and offsetting electricity emissions were more cost-effective.

“Since next-generation biofuels are still emerging, our model helps ensure we’re designing these systems correctly,” Maravelias said. “It’s crucial to have as much information as possible now to avoid committing to suboptimal technologies and system configurations.”