Researchers have developed a groundbreaking method to seal cracks in rocks, inspired by the natural process of fossilization.

This new “concretion-forming resin” can create durable seals that even survive earthquakes.

The team’s findings were published in Communications Engineering.

Disposing of hazardous materials like radioactive waste and carbon dioxide underground requires sealing the rock formations to prevent leaks.

However, traditional cement-based materials often fail to provide long-term durability, especially in earthquake-prone areas like Japan.

Hidekazu Yoshida, a lead researcher from the Nagoya University Museum, looked to his knowledge of fossil preservation for a solution.

Fossils preserved in calcium carbonate concretions remain intact for millions of years, even in weathered and earthquake-prone areas. Yoshida wondered if a similar approach could be applied industrially.

“I realized that fossils in concretions had withstood weathering and earthquakes for tens to hundreds of thousands of years,” Yoshida said. “This inspired me to study how fast concretions were formed and why the fossils inside were preserved so well.”

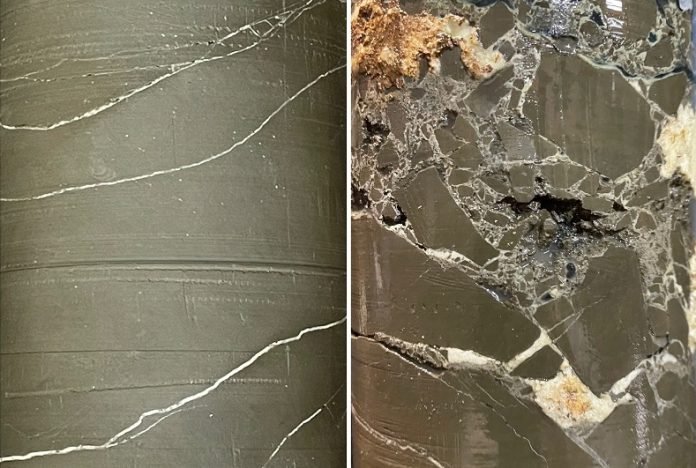

Concretions form when minerals in groundwater precipitate and accumulate around organic material, creating crystals that bind sediments and seal even tiny openings. Yoshida and his team developed a resin that mimics this process. When mixed with water, the resin forms calcite crystals that fill and seal cracks quickly.

The researchers tested this resin in an underground lab 350 meters below the surface in Hokkaido, Japan. The resin demonstrated excellent sealing abilities, even during six earthquakes, including a magnitude 5.4 quake, over two days. The sealed cracks remained intact, and any reopened cracks resealed as the crystals reformed.

“The earthquakes were a coincidence, something we never expected,” Yoshida said. “But it was a great opportunity to see the material’s performance. Conventional cement materials cannot achieve such fast-acting and sustained sealing, especially after earthquakes.”

The team is collaborating with the Japan Atomic Energy Agency, Sekisui Chemical Co., and Chubu Electric Power Co. to make the resin commercially viable. They envision it being used for long-term underground storage of radioactive waste and carbon dioxide, sealing abandoned oil wells, controlling groundwater during excavation, and repairing cracks in aging infrastructure like roads and buildings.

This innovative resin-based sealing method could revolutionize how we manage underground activities, providing a reliable and durable solution to prevent leaks and withstand natural disasters.