Researchers at Oak Ridge National Laboratory (ORNL) have developed an innovative technology that uses phase change materials (PCMs) to keep food refrigerated while reducing carbon emissions by 30%.

This breakthrough could make household refrigerators more efficient and environmentally friendly.

Currently, over 100 million refrigerators in the United States consume up to 2 kilowatts of electricity each day.

These appliances contribute significantly to energy consumption and carbon emissions due to their compressors, which cycle on and off around the clock to maintain low temperatures.

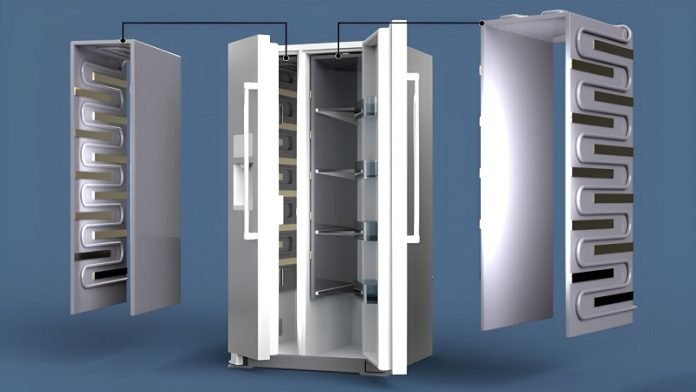

The ORNL innovation involves advanced evaporators with PCMs installed in both the fresh and frozen compartments of the refrigerator.

PCMs are materials that store and release energy when they change from solid to liquid or vice versa, making them ideal for heating and cooling applications.

By integrating PCMs with evaporator coils, the new technology can keep temperatures constant with fewer compressor cycles.

“PCMs are integrated with evaporator coils to keep temperature constant, requiring only one operating cycle and allowing refrigerators to operate almost 100% at nighttime, when energy use is lower,” said Zhiming Gao from ORNL.

“This reduces electricity demand, saves costs, and maintains efficiency.”

The researchers also used porous metals and direct-contact defrosting technology to enhance the performance of the PCMs.

Additionally, they selected a refrigerant with a low global warming potential to further minimize the environmental impact.

The new technology allows the refrigerator to cycle just once overnight, storing enough cold energy to keep food fresh throughout the day. This not only reduces the amount of electricity needed but also decreases the strain on power grids during peak hours.

In tests, the ORNL team demonstrated that the refrigerator maintained consistent temperatures and performed just as well as conventional models. The reduced need for frequent compressor cycles leads to significant energy savings and a substantial reduction in carbon emissions.

By using PCMs and other advanced technologies, ORNL’s innovation offers a practical solution to make household refrigeration more sustainable.

If widely adopted, this technology could have a significant impact on energy consumption and carbon emissions in homes across the country.

In summary, ORNL’s new refrigeration technology harnesses the power of phase change materials to keep food cool more efficiently, cutting carbon emissions by 30% and potentially revolutionizing the way we think about household appliances.

Source: Oak Ridge National Laboratory.