A team of researchers from Columbia Engineering has discovered how to use nuclear magnetic resonance (NMR) spectroscopy to design safer and better-performing lithium metal batteries.

Their findings were published in the journal Joule and could accelerate the development of these advanced batteries, which have been in the works for over four decades.

The research, led by Associate Professor Lauren Marbella, focuses on the anode surface of lithium metal batteries.

Unlike the graphite anodes used in current batteries, lithium metal anodes could make electric vehicle batteries cheaper and provide a longer range.

This advancement could revolutionize transportation, making electric semi-trucks and small aircraft more feasible.

Commercializing lithium metal batteries has been challenging because lithium is highly reactive. When exposed to the electrolyte in a battery, it quickly forms a passivation layer, similar to tarnish on silverware.

This layer, known as the solid electrolyte interphase (SEI), affects how lithium ions move during charging and discharging, impacting battery performance. If not properly managed, this can lead to the growth of metal filaments that degrade the battery.

Until now, it has been nearly impossible to measure the chemical composition of the SEI while also tracking how lithium ions move within it. Understanding these details could help scientists design better-performing batteries.

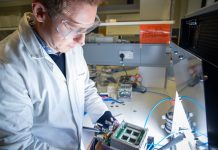

The team at Columbia Engineering has shown that NMR spectroscopy can provide this critical information.

NMR can directly measure how fast lithium ions move at the interface between the lithium metal anode and its SEI layer. It also identifies the chemical compounds present on the surface.

Unlike other methods, such as electron microscopy, which provides detailed images, NMR can pinpoint the exact chemical composition and track ion transport. This unique capability allows researchers to understand the relationships between the SEI’s structure and its properties.

By examining data collected over six years, the team found that NMR can detect changes in the SEI’s structure, explaining some of the mysterious connections between its composition and battery performance.

They discovered that when lithium metal is exposed to different electrolytes, the SEI’s composition changes, affecting how lithium ions reach the anode surface and improve battery performance.

For the best battery performance, the SEI needs to be arranged with specific chemical compounds layered on top of each other, rather than randomly distributed. This arrangement improves the rate at which lithium ions exchange with the surface, enhancing battery efficiency.

The researchers believe combining NMR with other techniques, such as microscopy, computer simulations, and electrochemical methods, will be essential for advancing lithium metal batteries. By using NMR, scientists can screen electrolyte formulations to find the best ones for high-performance batteries and identify the necessary SEI compounds for optimal performance.

Professor Marbella highlighted that NMR is one of the few techniques that can probe local structural changes in the SEI, such as the formation of amorphous or nano-sized lithium fluoride. This information is crucial for intentionally engineering these changes to design commercially viable lithium metal batteries.

Currently, Marbella’s group is using exchange NMR coupled with electrochemistry to better understand the SEI’s composition and properties in various electrolytes. They are also developing systems to determine how individual chemical components contribute to lithium-ion transport through the SEI.

This research represents a significant step toward safer, more efficient lithium metal batteries, potentially transforming the future of energy storage and electric transportation.

Source: Columbia University.