In an era where plastic plays an indispensable role in almost every aspect of modern life, from packaging to high-tech industries, the quest for sustainable alternatives to petroleum-based plastics has never been more critical.

The challenges posed by plastic waste, which accumulates in landfills and oceans, polluting ecosystems and harming wildlife, have spurred scientists to search for greener solutions.

Researchers at the FAMU-FSU College of Engineering have made a significant breakthrough in this endeavor, crafting a potential game-changer for the industry from two unlikely sources: carbon dioxide (CO2) and lignin.

This pioneering research, showcased in Advanced Functional Materials, introduces a novel method of creating degradable polymers from CO2, a notorious greenhouse gas, and lignin, a low-cost byproduct of paper production and biofuel manufacturing.

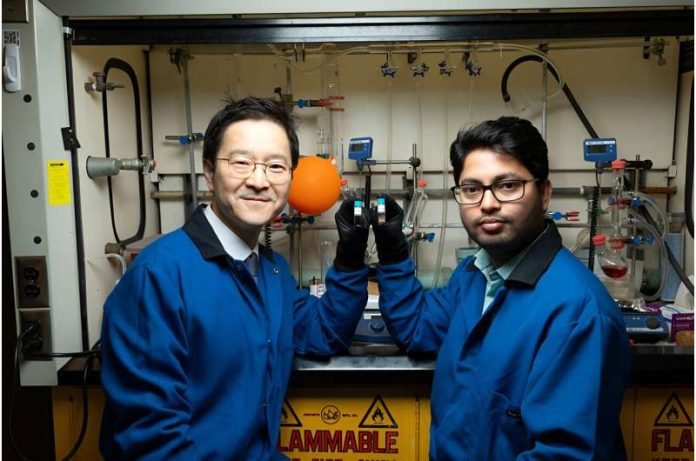

Led by Associate Professor Hoyong Chung, the team’s innovation not only offers a route to mitigate CO2 emissions but also turns it into a valuable resource for producing sustainable plastics.

At the heart of their discovery is the direct synthesis of a cyclic carbonate monomer, a molecule that serves as a building block for creating synthetic polymers.

These long-chain molecules are vital for a myriad of applications, shaping everything from everyday items to advanced industrial materials.

The breakthrough lies in the ability to form these monomers directly from CO2 and lignin, a process that was not previously demonstrated.

The significance of this new polymer extends beyond its eco-friendly raw materials. Unlike traditional plastics, which often end in landfills or the ocean, breaking down into harmful microplastics, the material developed by Chung’s team is fully degradable.

It breaks down without leaving behind toxic substances or microplastics. Furthermore, it can be synthesized under lower pressures and temperatures, making the production process more energy-efficient.

Recycling plays a crucial role in the lifecycle of this innovative material. The researchers have developed a method to depolymerize, or break down, the polymers back into pure monomers.

This capability ensures that the material can be recycled without degrading its quality, unlike current plastics, which suffer quality loss and limited recyclability due to repeated heating.

Chung’s team envisions a true circular economy for plastics, where materials can be endlessly recycled without losing their original properties.

The applications for this sustainable polymer are vast and varied. Initially, it could replace conventional plastics in sectors requiring low-cost, short-lifespan products such as construction, agriculture, packaging, and disposable items in cosmetics and kitchenware.

The team also sees potential for its use in developing specialized polymers for critical sectors like biomedicine and energy storage.

The study, led by postdoctoral researcher Arijit Ghorai, marks a significant step forward in addressing the environmental impact of plastic waste.

By harnessing the power of chemistry to convert CO2 and lignin into valuable polymers, this research paves the way for a future where plastics contribute to sustainability rather than environmental degradation.

The research findings can be found in Advanced Functional Materials.

Copyright © 2024 Knowridge Science Report. All rights reserved.