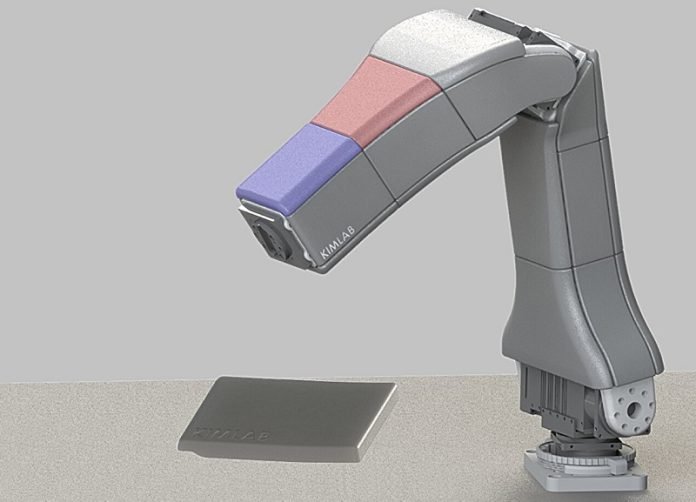

Researchers at the University of Illinois Urbana-Champaign are transforming the way robots interact with humans by using 3D printers to create soft skin pads that serve as touch sensors.

These innovations, described in the journal IEEE Transactions on Robotics, make robots not only safer but also more intuitive for human interaction, enhancing their use in everyday environments.

The project, led by Joohyung Kim, a professor of electrical & computer engineering, focuses on addressing the challenges of working safely with robots.

“Robotic hardware often involves large forces and torques, so ensuring safety is crucial, especially in direct human interactions or in environments frequented by humans,” explains Kim.

The soft skin developed through this research is pivotal in making robots safer and more sensitive to touch.

This new type of robotic skin is crafted from thermoplastic urethane—a material ideal for these applications due to its durability and flexibility.

The process involves 3D printing pads that are not only soft but also embedded with air-tight seals.

These seals are connected to pressure sensors so that when the pad is touched or pressed, it deforms like a squeezed balloon. The change in air pressure within the pad activates the sensor, allowing the robot to detect and react to physical interactions.

The simplicity and cost-effectiveness of producing these 3D-printed pads are among their greatest advantages.

Unlike traditional tactile sensors, which can be complex and costly, these 3D-printed alternatives are affordable and can be quickly produced and customized for different robotic systems.

“The beauty of using 3D printing for these sensors is that they can be easily adapted and replaced, making them ideal for environments where maintaining hygiene is crucial, like hospitals,” Kim remarks.

These tactile pads enable robots to stop automatically if something or someone is detected near a potentially dangerous area, like a joint.

They can also interpret different touches and taps as specific commands, adding a layer of functionality that goes beyond basic operational tasks.

The broader implications of this technology are significant, particularly in how robots perceive and interact with their environment. Most robotic systems currently rely heavily on computer vision and language processing to interact with humans.

However, the physical interaction data that these soft skins can provide is invaluable for developing more responsive and aware robotic systems.

Kim is optimistic about the future applications of this technology, especially in collecting detailed data about physical interactions, which he sees as crucial for the next generation of robotic systems.

This research not only paves the way for safer human-robot interactions but also opens up new possibilities for how robots can be integrated into more aspects of daily life.