Researchers at MIT have developed a groundbreaking method that could significantly enhance the strength and durability of materials used in airplanes and spacecraft.

This new technique, known as “nanostitching,” involves integrating carbon nanotubes into composite materials to prevent them from cracking.

The study, recently published in the journal ACS Applied Materials and Interfaces, points to a future where these advanced materials could make our vehicles lighter and more fuel-efficient, while also reducing emissions.

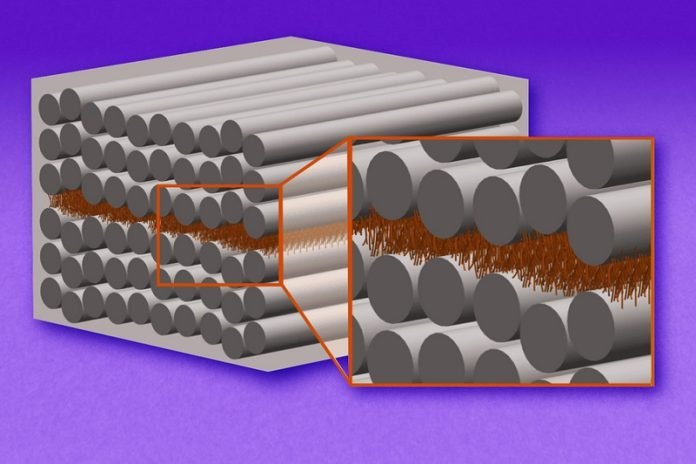

Composite materials are engineered from high-performance fibers embedded in polymer sheets. These sheets are layered and pressed together to form strong, lightweight structures ideal for various high-tech applications.

However, these materials have a critical weakness: the spaces between layers.

These are typically bonded with a polymer “glue,” but can easily crack under stress, weakening the material over time without visible signs of damage.

The MIT team, led by Professor Brian Wardle, introduced carbon nanotubes into these vulnerable interlayer spaces.

Carbon nanotubes are minuscule, hollow cylinders of carbon that are incredibly strong and lightweight.

By growing forests of these tubes chemically and embedding them between the composite layers, the researchers created a strong bonding that acts like super-strong Velcro. This bonding prevents the layers from peeling apart or shearing under stress.

In tests involving a type of composite known as thin-ply carbon fiber laminate, which is thinner and potentially stronger than standard composites, the “nanostitched” materials showed up to 60% better resistance to cracks compared to those bonded with traditional polymers.

The concept of nanostitching was first developed in Wardle’s lab, called the necstlab (pronounced “next lab”).

The process starts with chemically growing the nanotubes in an oven through a method called chemical vapor deposition.

This technique allows the carbon to form into tiny, hair-like structures, which are then aligned and embedded into the composite layers.

The experiments for this study were spearheaded by Carolina Furtado, who started this project through the MIT-Portugal program and has continued her research as a professor at the University of Porto.

Furtado’s work mainly involved preparing the thin-ply carbon fiber laminate composites, embedding the nanotube forests between the layers, and then testing their resistance to cracking.

Testing involved deliberately starting a crack in the composite to see how far it would spread. The setup mimicked various types of stress that could cause layers to separate—a process known as delamination.

This includes impacts from objects or environmental factors, which typically do not show external damage but can internally weaken the composite.

The nanostitched composites resisted these stresses significantly better, preventing the initial crack from spreading further.

According to Professor Wardle, this new technology not only strengthens the materials but also makes them safer and extends their lifespan.

The potential applications of this technology are broad, ranging from aerospace to military vehicles, where the resistance to internal damage is crucial.

This advancement in composite technology could revolutionize how we build everything from aircraft to spacecraft, making them lighter, stronger, and more resilient.

With the ability to target specific areas for reinforcement, like bolted joints or regions prone to damage, nanostitching opens up new possibilities for designing and constructing the next generation of vehicles and structures.