Scientists at the University of Nottingham have made a significant breakthrough by transforming metal waste into a highly effective catalyst for producing hydrogen from water.

This discovery, detailed in the Journal of Material Chemistry A, could make the production of hydrogen, a clean and sustainable fuel, more environmentally friendly and cost-effective.

Hydrogen is an ideal clean fuel as it generates heat and powers vehicles while only emitting water vapor when burned.

However, traditional methods of producing hydrogen typically depend on fossil fuels, which are not sustainable.

Electrolysis, a greener method that splits water into hydrogen and oxygen using electricity, usually requires rare and expensive metals like platinum as catalysts.

The challenge has been the high cost and scarcity of these metals.

However, the research team from Nottingham’s School of Chemistry and Faculty of Engineering has found a way to use swarf—tiny particles of metal waste produced during the machining process—as a base for these catalysts.

Swarf is usually disregarded as scrap but has a unique nanotextured surface with grooves and ridges ideal for anchoring atoms of precious metals.

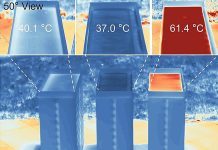

Dr. Jesum Alves Fernandes, who led the study, explained that using a scanning electron microscope, the team discovered that the seemingly smooth surfaces of stainless steel, titanium, or nickel alloy swarf actually feature nanoscale textures.

This unexpected finding opened the door to using swarf as a potential catalyst base.

The researchers applied a technique called magnetron sputtering to deposit platinum atoms onto the swarf.

These atoms cluster into nanoparticles that nestle perfectly into the nanoscale grooves, forming an efficient catalyst that requires far less platinum than conventional catalysts. Dr. Madasamy Thangamuthu, involved in the analysis, noted the remarkable efficiency of this process, stating that it uses only a tenth of the platinum typically needed.

In the lab, just 28 micrograms of platinum spread over one square centimeter of swarf produced a staggering 0.5 liters of hydrogen per minute.

The catalyst operates at 100% efficiency, meaning all the electrical energy used in the process is converted to chemical energy without waste.

This innovation not only reduces the need for new platinum but also repurposes metal waste from industries like aerospace, turning potential trash into a valuable resource. The team is now collaborating with AqSorption Ltd, a local company, to scale up this technology for commercial use.

Professor Andrei Khlobystov remarked on the dual benefits of this technology: reducing the use of precious metals and upcycling industrial waste.

This approach aligns with the goals of the Zero Carbon Cluster in the East Midlands, which aims to foster innovation in green industries.

Professor Tom Rodden from the University of Nottingham emphasized the broader implications of this technology, particularly for hydrogen propulsion systems in transportation and manufacturing, marking a significant step towards solving global zero-carbon challenges.