Researchers at the RIKEN Center for Sustainable Resource Science (CSRS) in Japan, led by Ryuhei Nakamura, have made a significant advance in green hydrogen production.

Their latest study, published in Nature Catalysis, showcases a custom-made catalyst that dramatically improves the sustainability and longevity of hydrogen extraction from water.

Hydrogen is a clean energy source, and producing it through water electrolysis is a green process.

This method involves splitting water into hydrogen and oxygen using electricity. The hydrogen can be stored and used later, for example, to power electric vehicles.

However, the process of splitting water, particularly using proton exchange membranes (PEM), faces challenges.

It requires rare earth metals like iridium, which are scarce and not sustainable for large-scale use.

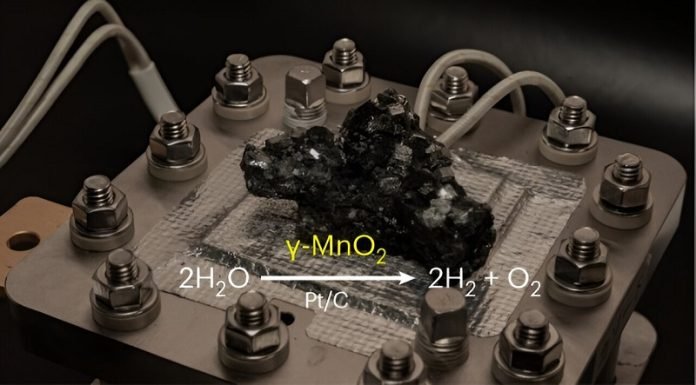

Two years ago, Nakamura’s team developed a new method that avoided these rare metals by using more common ones like manganese and cobalt.

Building on this, the team has now enhanced their catalyst, making it much more stable and increasing its lifetime by almost 4000%.

This catalyst, made from a form of manganese oxide (MnO2), underwent structural tweaks to improve its effectiveness.

By altering the arrangement of oxygen within the manganese oxide structure, they managed to enhance the stability of the catalyst significantly.

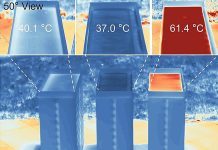

In the laboratory, this new catalyst was tested and shown to maintain its activity in harsh acidic conditions for extended periods—up to one month at high current densities.

This performance is a hundred times better than previous efforts with similar non-rare metal catalysts.

The study also highlighted that the improved catalyst could sustain water electrolysis for about six weeks, producing ten times more hydrogen than previous methods.

Remarkably, this increased stability did not reduce the catalyst’s efficiency in generating hydrogen.

Although these results are promising, more work is needed to reach the stability required for industrial applications, which demand consistent performance over several years. Nonetheless, the team is optimistic.

They plan to continue refining the catalyst to increase both its longevity and efficiency, aiming for a future where large-scale green hydrogen production is both sustainable and economically feasible.

This research represents a significant step towards reducing reliance on fossil fuels and moving towards a carbon-neutral future.

It also opens up the possibility of more sustainable hydrogen production methods becoming a practical reality, contributing to the global fight against climate change.