Researchers at Nanyang Technological University, Singapore (NTU Singapore), have developed a groundbreaking adhesive that is more than ten times stronger than the adhesion of gecko feet.

This new “smart” adhesive could revolutionize how we use superglue and enhance the capabilities of robotic grippers.

The NTU team, led by Professor K Jimmy Hsia, utilized shape-memory polymers to create this adhesive. Shape-memory polymers are smart materials that can remember their original shape and return to it when triggered by external stimuli like heat.

The team’s findings were recently published in the journal National Science Review.

The special feature of this adhesive is its ability to stick and detach easily, controlled by heating.

At room temperature, the adhesive is strong and can hold heavy weights, but when heated, it softens and can be easily removed.

This characteristic makes it an ideal solution for applications where temporary but strong adhesion is needed.

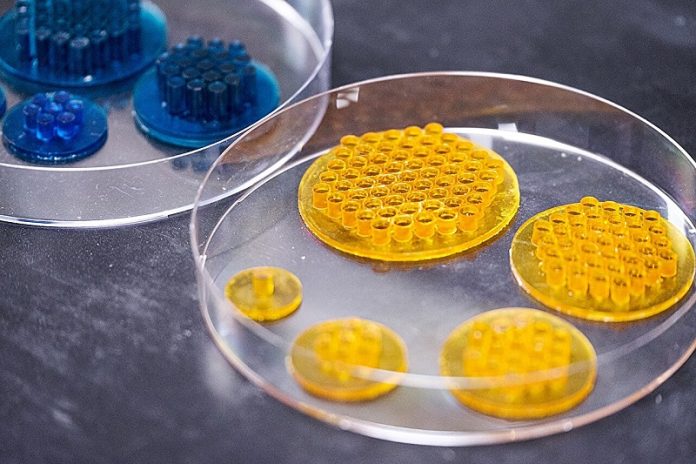

The design of the adhesive involves shaping the polymer into tiny hair-like structures called fibrils.

These fibrils are key to maximizing the adhesive’s grip on surfaces, both rough and smooth.

The optimal size for these fibrils, according to the research, is between 0.5 mm and 3 mm in diameter. This size allows the adhesive to maintain strong bonds without compromising the structure’s integrity.

In experiments, a single fibril could support weights up to 1.56 kg. A palm-sized array of 37 fibrils, which weighs about 30 grams, could hold up to 60 kg – roughly the weight of an adult human.

This impressive capacity opens up possibilities for its use in robotic applications and potentially in human climbing gear.

Dr. Linghu Changhong, the research paper’s first author, explained how this adhesive performs better on rougher surfaces, a breakthrough in understanding adhesion dynamics. “Our smart adhesive exemplifies how shape-memory polymers can maintain and even enhance adhesion as surface roughness increases,” said Dr. Changhong.

Co-corresponding author Professor Gao Huajian highlighted the practical benefits of the adhesive, emphasizing its strong yet easily detachable nature, which resolves the common conflict in adhesive technology between strength and ease of detachment.

The polymer’s transformation from hard to soft state and vice versa is controlled by temperature. Detaching the adhesive when it’s hard takes less than a minute with a hair dryer, while attaching it requires a few minutes to cool and lock into place. The researchers aim to reduce these times and lower the required temperature to make the adhesive even more versatile.

Looking ahead, the team envisions this adhesive being used in climbing equipment that would allow climbers to stick and scale walls effortlessly.

Additionally, wall-climbing robots equipped with this material could significantly benefit industries like construction and maintenance, making the technology a game-changer in both everyday and industrial applications.