Scientists are working on a breakthrough that could make monitoring chronic illnesses much easier and more affordable.

Using 3D printing technology, researchers at MIT have developed a crucial part of a mass spectrometer—a device used to identify chemical components in a sample, like hormone levels in blood.

This innovation could allow people with conditions such as hypothyroidism to easily check their health at home with a device as small as a shoebox.

Mass spectrometers are usually very expensive, often costing hundreds of thousands of dollars, which means they’re mainly used in labs.

Patients have to send their blood samples off for testing, a process that can be slow and cumbersome.

Luis Fernando Velásquez-García, a principal research scientist at MIT’s Microsystems Technology Laboratories, and his team aim to change this by creating a low-cost version of an ionizer, a key part of the mass spectrometer that prepares samples for analysis.

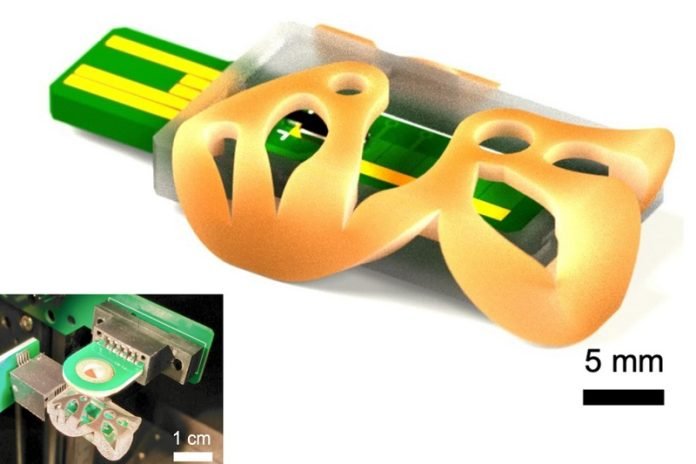

Their newly designed ionizer is not only cheaper to produce but also performs better than the more expensive versions currently used. By 3D printing this part, they were able to make it more precise and efficient.

This process allows for mass production in a way that could significantly lower costs and make the device accessible to more people.

The MIT team’s ionizer works by charging particles in a sample, a necessary step since the molecules in blood aren’t naturally charged.

Their version uses a technique called electrospray, which sprays charged particles into the mass spectrometer for analysis. The more charged particles the spray contains, the more accurate the results will be.

To create their ionizer, the researchers used a 3D printing method called binder jetting. This involves layering powdered metal and binding it together with a polymer glue, then heating it to create a solid object.

This method is precise and effective, and by tweaking the design and materials, the team was able to improve performance.

One innovative aspect of their design is how it handles evaporation, a common problem with electrospray that can lead to clogging.

The MIT researchers found a way to use evaporation to their advantage, designing the emitters to control the flow of liquid and increase the concentration of charged molecules.

The team also redesigned the electrode that applies voltage to the sample to prevent arcing—a problem that can damage the device.

With these improvements, their ionizer can operate at a higher voltage, which means it can ionize more molecules and produce clearer results.

Their work doesn’t stop at the ionizer. The MIT group is also developing other 3D-printed components necessary for a complete mass spectrometer, including a mass filter and vacuum pumps.

Their goal is to create a fully functional, compact mass spectrometer that could be used at home or in point-of-care settings, making it much easier for people with chronic illnesses to manage their health.

This advancement in 3D printing and mass spectrometry has the potential to transform how we monitor and manage health conditions, making it faster, cheaper, and more accessible for everyone.