3D printing has taken the world by storm, letting us create everything from simple toys to complex machine parts right from our homes and offices.

But there’s a catch: the plastic used in these printers isn’t great for the environment, and finding greener materials hasn’t been easy.

That’s because every new material requires a bunch of settings to be adjusted, a process that’s often done by guesswork and can be pretty tedious.

Enter a team of smart researchers from Carnegie Mellon University and other prestigious institutions.

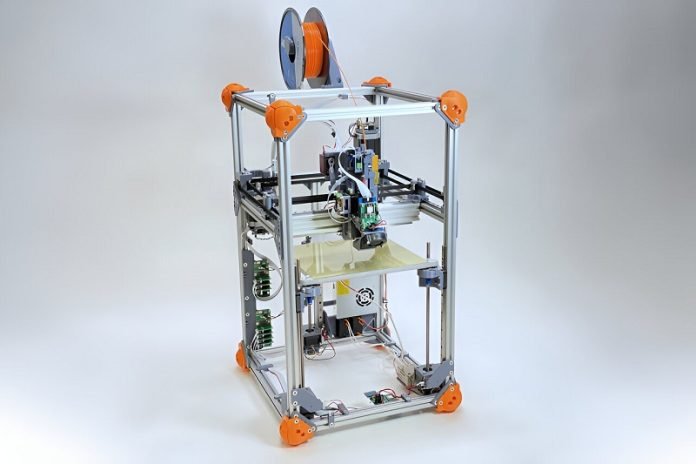

They’ve come up with a 3D printer that’s not only clever but also eco-friendly.

This printer can figure out how to print with any material thrown at it, even if it’s never seen it before.

Imagine being able to print with materials made from plants or recycled plastics without having to fiddle with dozens of settings!

The secret sauce of this printer lies in its extruder – that’s the part of the printer that pushes out the material to create objects.

The team tweaked this extruder to measure how the material flows and how much force it needs to push it through.

By running a short test that takes about 20 minutes, the printer gathers enough data to guess the best settings for that material. Then, voilà, it’s ready to print with it.

Why is this so cool?

Well, traditional 3D printers rely on specific settings for different materials, which means lots of trial and error. But this smart printer cuts through all that hassle, making it easier to use materials that are better for our planet.

Think about the variety of materials out there, especially the eco-friendly kinds. Their properties can change a lot – a bio-based material might vary with the seasons, depending on the plants used to make it.

This printer’s ability to adapt on the fly opens the door to using these variable materials without a hitch.

The team didn’t stop at making the printer smart. They also embarked on a mission to make 3D printing more sustainable.

Their printer, dubbed JoulesEye, can handle materials that traditional printers can’t, especially those that vary a lot or have unknown properties.

In tests, JoulesEye was able to print complex objects with a bunch of different materials, including several eco-friendly ones, with an impressively low error rate. This is a big step towards reducing the environmental footprint of 3D printing, which has traditionally relied on materials that aren’t so kind to our planet.

Looking ahead, the researchers want to make this process even smoother by integrating it directly into 3D printing software, so users won’t have to manually enter the settings. They’re also aiming to refine their method to account for even more variables in the printing process.

This innovation isn’t just good news for the environment. It could revolutionize how we think about and use 3D printing, making it more accessible, versatile, and sustainable.

By embracing locally sourced, sustainable materials, this smart 3D printer brings us one step closer to a future where digital manufacturing goes hand in hand with protecting our planet.