Researchers from KU Leuven and imec have made significant strides in advancing flexible electronics, a technology that could revolutionize how we use devices in everyday life.

Unlike traditional rigid silicon chips, thin-film transistors (TFTs) can bend and flex, opening up new possibilities for products like wearable health monitors and bendable screens.

Traditionally, the electronics industry has relied on silicon semiconductors, essential for modern technology but limited by their inflexibility.

This drawback sparked interest in TFTs, which are more adaptable and could potentially transform various sectors including healthcare, robotics, and the Internet of Things (IoT).

Despite their potential, the use of TFTs has been largely confined to controlling pixels in smartphone screens and other displays.

This limited application has restricted the creativity of designers eager to explore the broader possibilities of flexible microchips.

To address this, the research team, led by Professor Kris Myny, has demonstrated that a foundry business model, similar to that used in conventional chip manufacturing, can also be applied to thin-film electronics.

In the foundry model, specialized factories mass-produce chips designed by other companies.

This system has fueled the rapid growth and innovation of the silicon chip industry by allowing designers to create customized chips without needing their own manufacturing facilities.

By adopting this model for flexible electronics, the team believes it can significantly accelerate innovation in this field.

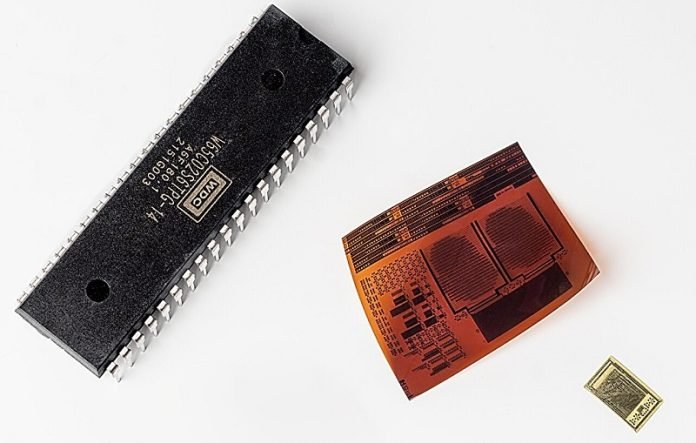

They proved their point by successfully designing and producing a flexible version of the iconic MOS 6502 microprocessor, a chip fundamental to early computers by Apple, Commodore, and Nintendo.

The researchers manufactured the chip in two versions using different substrates, showing the versatility of the approach.

The chip, thinner than a strand of human hair, is ideal for applications where comfort and flexibility are crucial, such as medical patches that monitor heart or muscle function and feel just like a skin sticker.

Although the performance of these thin-film chips doesn’t match modern microprocessors, their potential for flexibility offers a unique advantage that could lead to innovative applications beyond the capabilities of traditional silicon chips.

This breakthrough paves the way for more widespread use of flexible electronics, potentially leading to more comfortable and less intrusive wearable devices.

Professor Myny emphasizes that the goal isn’t to replace silicon chips but to expand the horizons of what’s possible in electronics through the use of flexible, thin-film technology.

Source: KU Leuven.