In a groundbreaking stride at Stanford University, researchers have unveiled a novel microscale 3D printing technique, propelling the possibilities in medicine, manufacturing, research, and more.

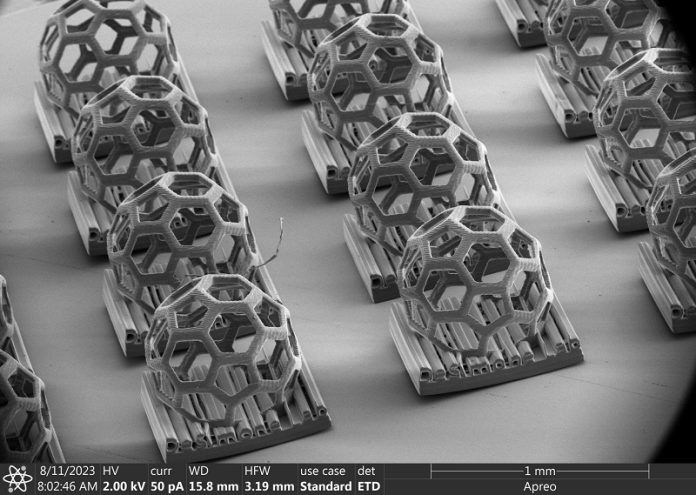

Imagine creating tiny particles, almost invisible to the naked eye, at a staggering rate of up to 1 million pieces daily.

These minuscule creations, resembling specks of dust, are set to transform the realms of drug delivery, microelectronics, and beyond, ushering in a new era of precision and scale.

Leading the charge, Jason Kronenfeld, a Ph.D. candidate at the DeSimone lab, shares their team’s success in crafting complex shapes at microscopic levels, a feat unparalleled in the speed of particle fabrication.

This innovation springs from an advanced printing method known as CLIP, first introduced in 2015. CLIP’s magic lies in using UV light to shape resin quickly, thanks to an oxygen-permeable window that ensures smooth and rapid printing.

Joseph DeSimone, a pioneer at Stanford, emphasizes the transformative potential of molding objects with light, sans molds, envisioning a future where these particles drive industries forward.

The secret sauce?

A novel process dubbed roll-to-roll CLIP, or r2rCLIP, which mirrors an assembly line. Here, shapes are printed en masse onto a film, which then undergoes washing, curing, and removal – all in a streamlined, automated fashion.

This method marks a significant leap from the manual, time-consuming processes of yore, achieving fabrication rates once deemed impossible.

DeSimone’s lab is not just about crafting prototypes but enabling mass production, bridging the gap between the laboratory and the industrial scale. The balance between speed and resolution is crucial, with the team’s approach striking a perfect harmony essential for wide-ranging applications.

This pioneering work doesn’t stop at hard materials like ceramics; it also encompasses soft particles like hydrogels, opening doors to innovative applications in microelectronics and drug delivery.

As the field of 3D printing evolves, the focus shifts from the intricacies of the process to the endless possibilities of the products themselves.

In essence, Stanford’s latest advancement in microscale 3D printing is not just a technical marvel but a beacon of potential, setting the stage for a future where the tiny particles we can barely see hold the power to revolutionize industries and improve lives.