In a world where clothing waste is a growing problem, a team of researchers from Lund University in Sweden has made an exciting breakthrough.

They’ve developed a method to create new viscose fabric from old, worn-out cotton textiles, such as bed sheets.

This discovery could significantly reduce our reliance on forest resources for clothing production and help address the environmental impact of textile waste.

Typically, when we think of recycling, images of sorting plastics, metals, and paper come to mind.

However, the recycling of textiles, especially into high-quality materials, presents a unique set of challenges.

The main obstacle lies in the nature of cotton fibers themselves. These fibers are long and complex, treated with a variety of chemicals for dyeing and protection, and over time, accumulate grime from everyday use.

Despite these challenges, Edvin Bågenholm-Ruuth and his team have pioneered a technique to transform these tough, treated fibers back into soft, versatile viscose fibers. Viscose, often known as artificial silk, is a popular material found in a variety of garments like blouses, skirts, and dresses.

The traditional process for making viscose uses cellulose from wood pulp, but this innovative approach repurposes cellulose from used textiles instead.

This groundbreaking method not only promises to save forests but also aims to make the textile industry more sustainable.

While there have been attempts to create viscose from recycled cotton in the past, those efforts have often relied heavily on mixing in new, or “virgin,” fibers to achieve a satisfactory product.

The Lund University team, however, has demonstrated that their process can produce high-quality viscose fibers without the need for such mixtures.

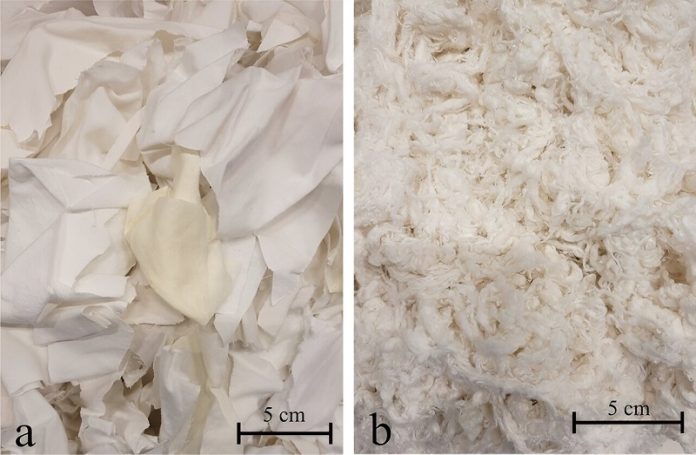

The secret to their success lies in a surprisingly simple chemical, zinc chloride, which, when mixed with water, can break down cotton textiles into a substance ready for transformation. After treating the material with zinc chloride, it turns into a mushy mass.

With the addition of water, this mass yields a fluffy white substance known as “dissolving pulp.”

This pulp can then undergo further processing, involving chemicals like carbon disulfide and sodium hydroxide, to eventually become viscose fibers. Impressively, their method requires less carbon disulfide than traditional processes, making it less harmful to the environment.

One of the next steps for this research is to address the challenge of colored textiles. The current process works best with white fabrics, but for colored or dyed textiles, an additional step to remove color might be necessary. The goal is to find a way to do this without resorting to traditional, environmentally harmful bleaching methods.

The success of this research could revolutionize the way we think about textile waste. By converting old cotton sheets into new viscose textiles, we can reduce our environmental footprint, save valuable forest resources, and take a significant step towards a more sustainable fashion industry.

With plans for a pilot plant in Europe in the near future, this innovative method holds great promise for reducing the impact of our clothing on the planet.